Hall 3.2 – Booth 100 E

#PostCarbon #RailwayStationDesign #MultiDisciplinarity #UrbanPlanning #Research #EMC2B

about us :

Founded in 1997 and a subsidiary of SNCF Gares & Connexions, the AREP group brings together a wide range of skills: in architecture through its company AREP Architectes, in urban planning, design, engineering, programming, people movement, consulting and project management. With its subsidiaries in France and abroad, the group provides concrete responses to the challenges of the ecological emergency through its EMC2B approach (Energy, Materials, Carbon, Climate, Biodiversity). It contributes to research, public debate and the development of practices through its publications, in particular its magazine POST. With offices in France and abroad, the AREP group employs nearly 1,000 people of 30 different nationalities.

Post-carbon Railway Stations

The AREP Group is at the forefront of ecological transition and designs future post-carbon railway stations, in France and abroad. EMC2B is our framework for making post-carbon operational. EMC2B weights the ecological footprint of a project, at all scales. EMC2B is a metric system that can be used to assess the five transitions that all projects must address. Using specific values, we identify the quantity of materials used and their origin (materials), greenhouse gas emissions (carbon), energy consumption and production (energy), albedo (climate) and the number of trees preserved or planted (biodiversity).

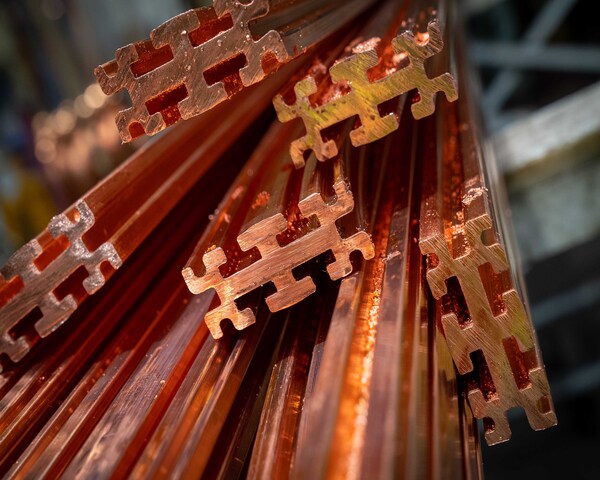

Train maintenance facilites

The AREP group has been designing and building maintenance workshops and technical railway buildings for over twenty years, both new and refurbished, including on operating sites.

Our projects reflect a sustained focus on today’s business practices and how they evolve, on understanding processes and how they are transposed into buildings, and on the modularity of spaces to extend the life of our projects without compromising future uses.

Plunging these projects into a post-carbon future means above all thinking about their adaptability, within their environment and over time.

Interior design of trains

A partnership between AREP and NENDO was formed in 2018 to create a surprising and refreshing new experience in the railway environment. This project is part of the overall design of the new French Inoui TGV. The concept for the project, « flow », was based on a very simple idea: the train looks like no other means of transport, it makes its way through the landscape, rather like the flow of a river. The project team played with the idea of depth inside, with a strong horizon line running through all the elements, giving the impression of the surface of water. Below this line, the materials are darker, and above it, everything is lighter to create a strong atmosphere and to ensure a long life in use.

OUR ECO-RESPONSIBLE COMMITMENTS :

To take action and give concrete expression to our ambition to build the ecological transition, we have devised the EMC2B approach for energy, materials, carbon, climate and biodiversity.

EMC2B is a metric system that can be used to assess the five transitions that all projects must address, and is our blueprint for making the post-carbon era operational. This approach is open and free to share, because we all have a common objective: to preserve the habitability of cities, regions and, more generally, the planet.

CONTACT US

16 Avenue d’Ivry – 75013 – Paris – FRANCE

E-mail: fabien.clavier@arep.fr

Tél. : +33 (0)6 34 78 53 88

www.arep.fr