Hall 3.2 – Booth 210 Q

#Celduc #SolidStateRelays #SSR #Sensors

about us :

Celduc® Relais is an innovative manufacturer of Solid State Relays, Magnetic Sensors, Reed Relays and Switches. With a highly automated factory, located near Lyon in France, and our network of subsidairies and distributors, we can support your requirements worldwide.

Since 1964 Celduc has been focused on manufacturing high-reliability switching and sensing devices. Our expertise in the development and production of Solid State Relays, Magnetic Sensors, Reed Relays and Switches for railway applications has given us access to major markets around the world. If our large selection of standard products does not meet your needs, we can discuss our custom solutions to help you optimize your design.

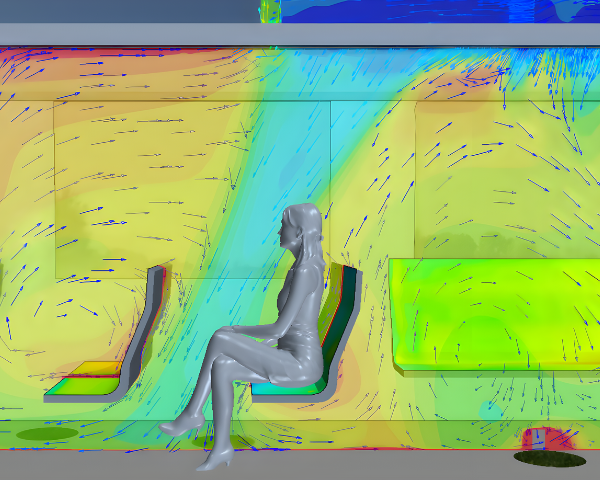

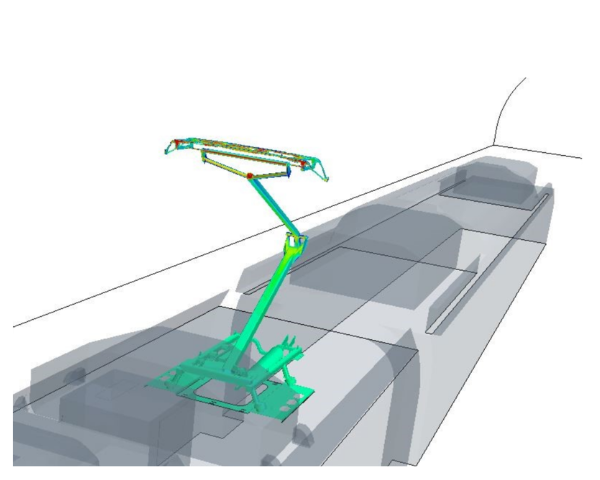

Large temperature variations, shocks, vibrations, electromagnetic interferences, and more : electrical components for the railway industry must provide safe and reliable operation even under extreme conditions. celduc’s SSRs are known for their high reliability and long electrical life, making them ideal to guarantee a better reliability and durability of your railway installations!

We have been a reliable and experienced partner in the railway industry for many years. You can rely on our solutions !

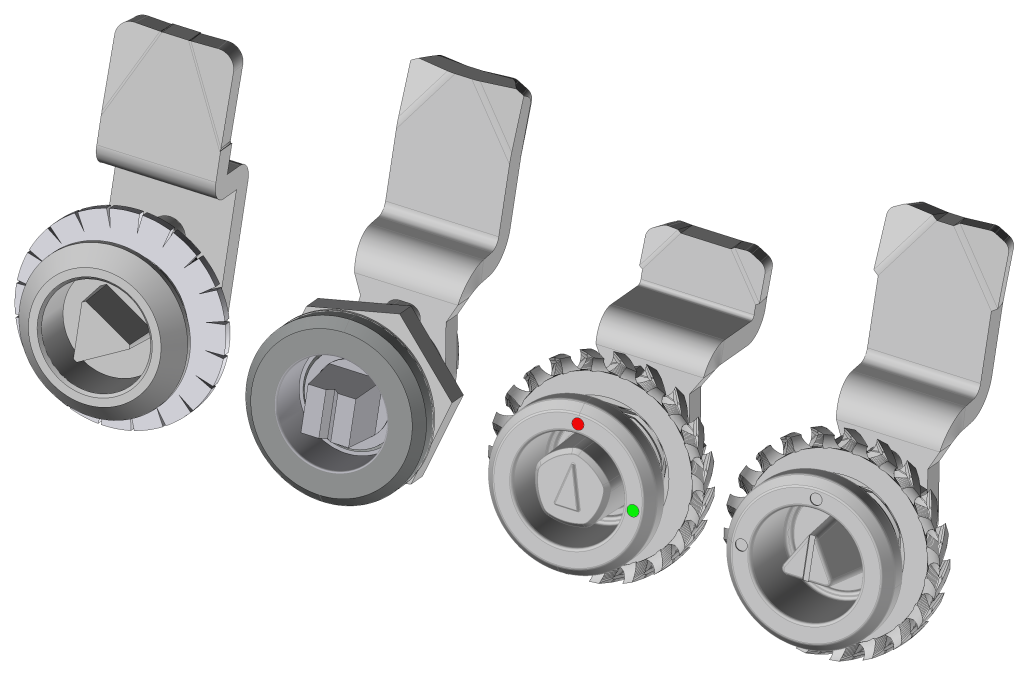

Celduc Solid State Relays are widely used across the railway industry because of their ability to function in harsh environments (dust, shocks and vibrations). Fully electronic, SSRs have no mechanical moving parts, so they have a longer service life compared to EMRs. In addition, their semiconductor based design makes them environmentally safe.

The IGBT based SSR (SDI Series) can switch up to 100 A @ 750 VDC nominal in a fast, reliable and safe way. This range is suitable for controlling High voltage heaters and helps to resolve maintenance problems that you have with your electromechanical contactors and improve the temperature control of your system.

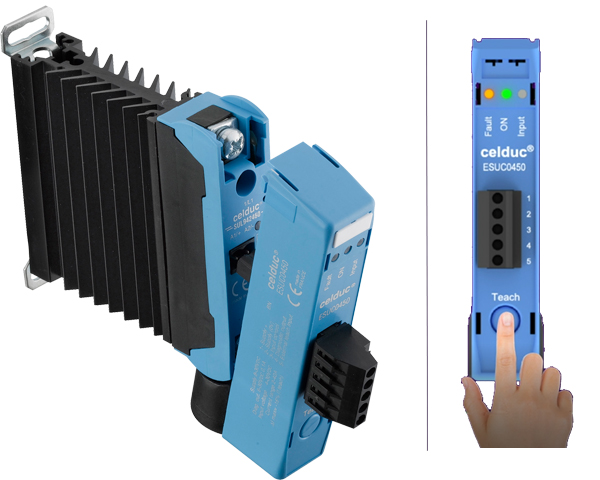

Add a diagnostic function to our Solid State Relay for Status feedback for safety ! Our ESUC optional module is pluggable directly on SU Series Solid State Relays and permanently measures the load current in order to make a diagnostic up to 5 heating elements in parallel. It allows a real-time control of the correct operation of your installation.

CONTACT US

celduc® relais, 5 rue Ampère – 42290 SORBIERS – FRANCE

E-mail : areynaud@celduc.com

Tél. : +33 (0)4 77 53 90 21 / +33 (0)4 77 53 90 19

www.celduc-relais.com