Hall 11.2 – Booth 270 F2

#RailwayRefurbishing #RollingStock #Trains #SubwayTrains #Trams #SubAssembliesComponents

about us :

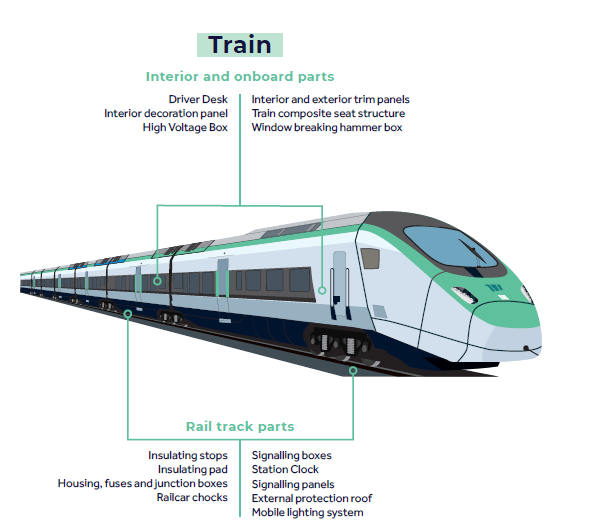

ACC M strives to develop a wide variety of customers and is aimed at the main operators of rail networks and their operators, in France, in Europe and around the world. ACC M has always maintained its commitment to a policy of raising the technical level of the services offered to its customers.

Today ACC M asserts itself as the leading independent specialist in railway equipment by continuously developing its know-how for the benefit of the reliability of its production and respect for the environment.

Expertise and skills variety allow ACC M, to answer exactly to trains refurbishing needs. At the same time lower the cost and increase the quality of its services. Both meeting deadlines.

ACC M teams are always looking for optimal solutions.

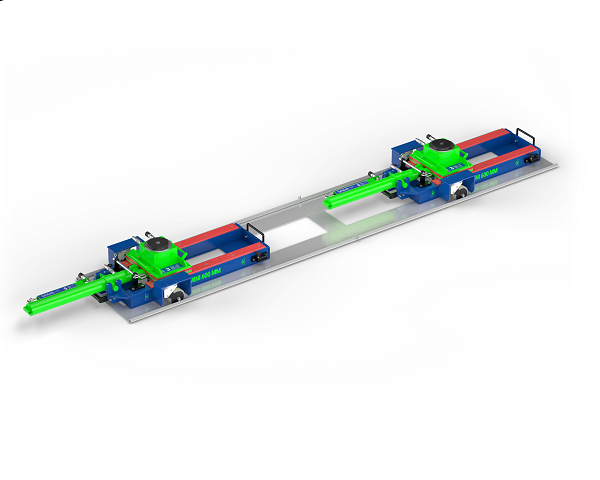

Trains are brought to the ACC M site by rail or by trucks with more than 30m trailers.

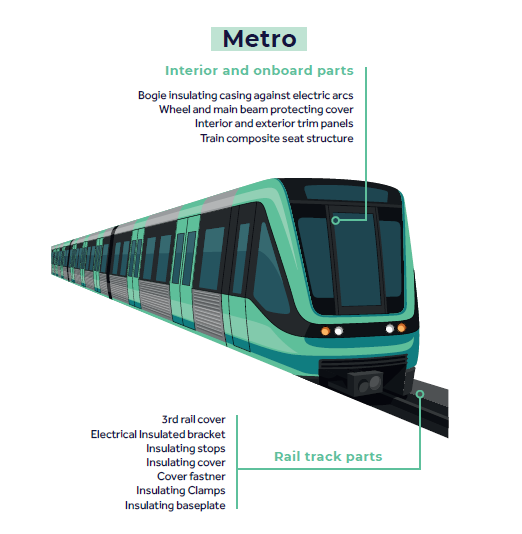

ACC M is an expert in the renovation and overhaul of subway trains

whether they are on tires or on iron wheels and regardless of the guidance system.

ACC M is an expert in the renovation and overhaul of trams

whether they are on tires or on iron wheels and regardless of the guidance system.

OUR ECO-RESPONSIBLE COMMITMENTS :

Ecovadis

CONTACT US

ACC M, 32 Rue du Pré la Reine – 63100 Clermont-Ferrand – France

E-mail : contact@acc-m.fr

Tél. : +33 (0)4 73 98 38 38 / +33 (0)6 66 94 49 14

https://www.acc-m.fr