about us:

Critical systems, innovative engineering

For over 20 years, Systerel has been creating, designing and implementing innovative solutions in the area of real time and safety critical systems.

Specialized in critical software and RAMS (Reliability / Availability / Maintainability / Safety), its railway activities focus mainly on CBTC, interlocking and ERTMS systems.

Its expertise covers a wide range of skills:

· Design, development, verification and validation or software assessment at all safety levels

· Building of a full safety case up to its approval by a certification authority

· Related activities: methodology, formal methods, architectural study, tools

The company also provides industrial solutions to enhance systems safety and security, reducing costs and time-to-market:

· S2OPC: safe & secure implementation of OPC UA standard

· Systerel Smart Solver: safety proof for systems, using formal verification

· OVADO²®: formal generation and validation of critical configuration data

· BLAST: optimization of railway balise positioning

Systerel’s integration of advanced technologies, combined with deep industrial knowledge, enables the delivery of highly innovative and competitive solutions for safety-critical railway systems.

Since its creation, Systerel has built strong partnerships with industry leaders, such as Alstom, Hitachi Rail, RATP, Siemens, SNCF and Thales.

Formal verification solutions

Systerel develops innovative formal verification solutions to reduce development costs and time-to-market:

- Systerel Smart Solver: safety proof for systems using formal verification

- OVADO²®: formal generation and validation of critical configuration data

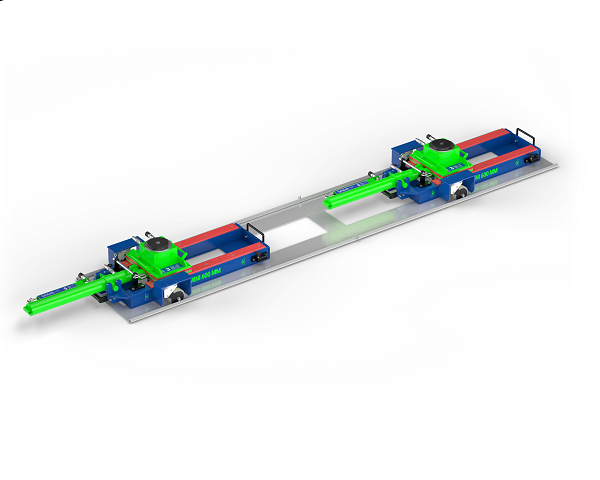

- BLAST: optimization of railway balise positioning

Interlocking on COTS SIL2/SIL4 PLC

- A digital twin enables both early functional validation and complete formal verification of safety

- Generic safety properties cover all configuration of your system

- Instantiation to each specific signaling area of your system is achieved through a track plan editor

- Final proof ensures global safety

Critical software, RAMS and cybersecurity

- System and Software development, verification, validation or evaluation activities, up to SIL4 (EN50126/28/29)

- Full safety case and safety assessment

- Implementation of cybersecurity standards (IEC62443) and OPC UA expertise

OUR ECO-RESPONSIBLE ENGAGEMENTS:

As player in the digital world, Systerel has taken active steps to minimize its environmental impact. The company is a proud signatory of the Planet Tech’Care manifesto, pledging to measure and reduce the environmental footprint of its services. Alongside this commitment, Systerel implemented initiatives for effective electronic waste management and consistently encourages its employees to engage in environmental and community-focused activities. Furthermore, Systerel obtained the Silver Medal from EcoVadis, the world’s leading provider of sustainability assessments.