Hall 11.2 – Booth 270 E2

#Copper #Sustainability #Upcycling #Energy #Emobility #Components

about us :

Since 1823, Gindre has been proud to meet the challenges of the energy transition by providing industry with innovative and sustainable solutions based on our expertise in the transformation and distribution of copper semi-finished products and components.

A key metal in electrification, our group is vertically integrated, from smelting to distribution, via the manufacture of semi-finished products and components. We start with recycling, and support our customers right from the design stage of their applications, in optimizing their energy consumption and therefore their copper consumption.

We play a key role in the future of railways and sustainable mobility, whether in terms of infrastructure and networks (substations, catenaries) or locomotive traction systems (connections, busbars, batteries).

Our values: Innovation; Sustainability; Commitment; Caring; Cooperation are our identity. They shape our heritage and our future, and unite our teams towards common goals for lasting positive impact.

UPCYCLING AND RAW MATERIALS

Vertically integrated, GINDRE is perfectly in tune with the circular economy, where our copper billets are produced after electrolysis from waste. As a result, we have one of the lowest carbon footprints on the market, and we are keen to reassure our customers in a context where copper will be one of the critical metals

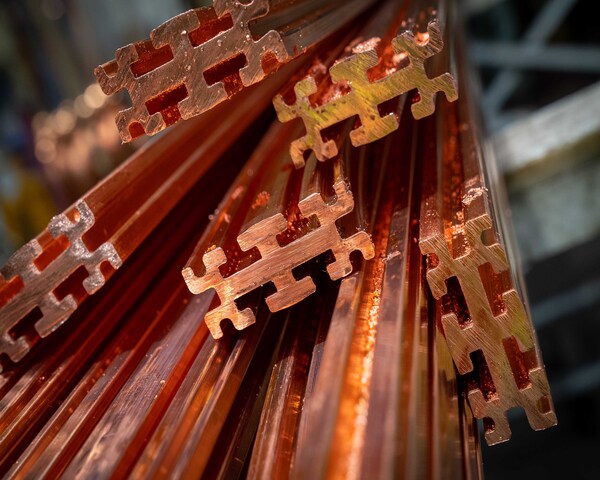

SEMI-FINISHED PRODUCTS AND COPPER OPTIMIZATION

GINDRE masters its extrusion and drawing processes to produce copper bars, coils and profiles. We design, manufacture and maintain our own tools, optimizing the copper to suit the electrical application. Profiles are the products of the age to reduce copper consumption, increase energy performance and enable faster assembly of systems.

COMPONENTS AND SOLUTIONS

GINDRE has plants for the manufacture of rigid or flexible copper components. These components are used to conduct electricity from the catenary to the train (pantograph bows) or to transmit current in locomotive traction modules (connections). At design phase, we optimize the copper cross-section and busbar routing between other train components.

OUR ECO-RESPONSIBLE COMMITMENTS :

EcoVadis

ISO14001

Team For the Planet

CONTACT US

BP 23, 31 RUE GIFFARD, 38230, PONT-DE-CHERUY – France

E-mail : sales.gdi@gindre.com

Tél. : + 33 (0)4 72 46 09 00 / + 33 (0)4 72 46 98 60

www.gindre.com