A7-7108

#MedicalDevice #ContractPackaging #Thermoforming #ThermoplasticInjection #LiquidSiliconeInjection #MoldManufacturer

about us :

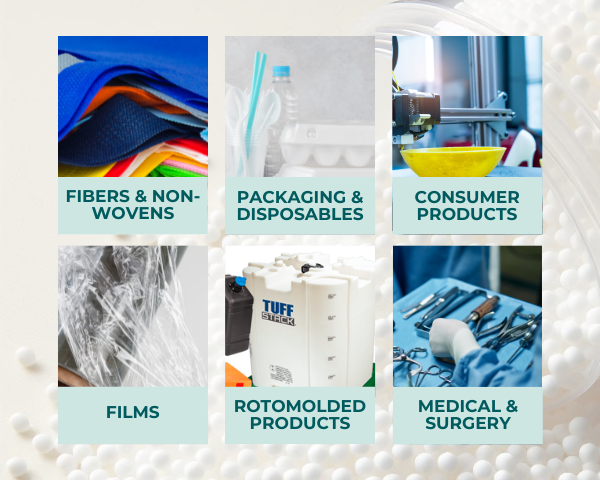

Top Clean Packaging is a family-owned international group specializing in the development and manufacture of medical devices, packaging and technical parts for the healthcare, luxury goods and industrial sectors.

Our combined expertise enables us to offer you the most comprehensive service possible, making us your single point of contact for all your projects. As a specialist in high technology and ultra-cleanliness, we provide support and advice to help you create a high-quality technical product.

At our various production sites, we master the following technologies: thermoforming, thermoplastics injection, silicone injection, sealing, assembly and packaging, cutting and screen printing.

Thanks to our many years of experience and state-of-the-art facilities, we do everything we can to ensure that your projects are a success.

Liquid Silicone Rubber injection

Specializing in Liquid Silicone Rubber (LSR) injection, we develop and manufacture products and components for various industrial applications including babycare, cosmetics, energy, and technical sports. We ensure optimal quality and precision for every project.

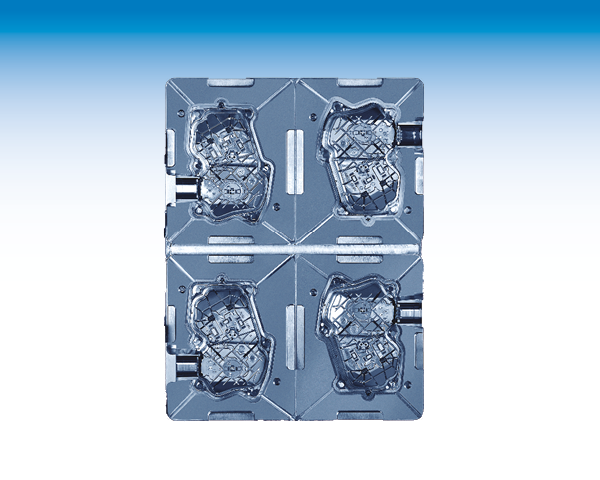

Trays for transportation and automated machines

As a European leader in thermoformed parts design and manufacturing, we offer technical trays meeting the most demanding market needs. We transform all types of plastic up to 1.2 meters wide, providing custom solutions.

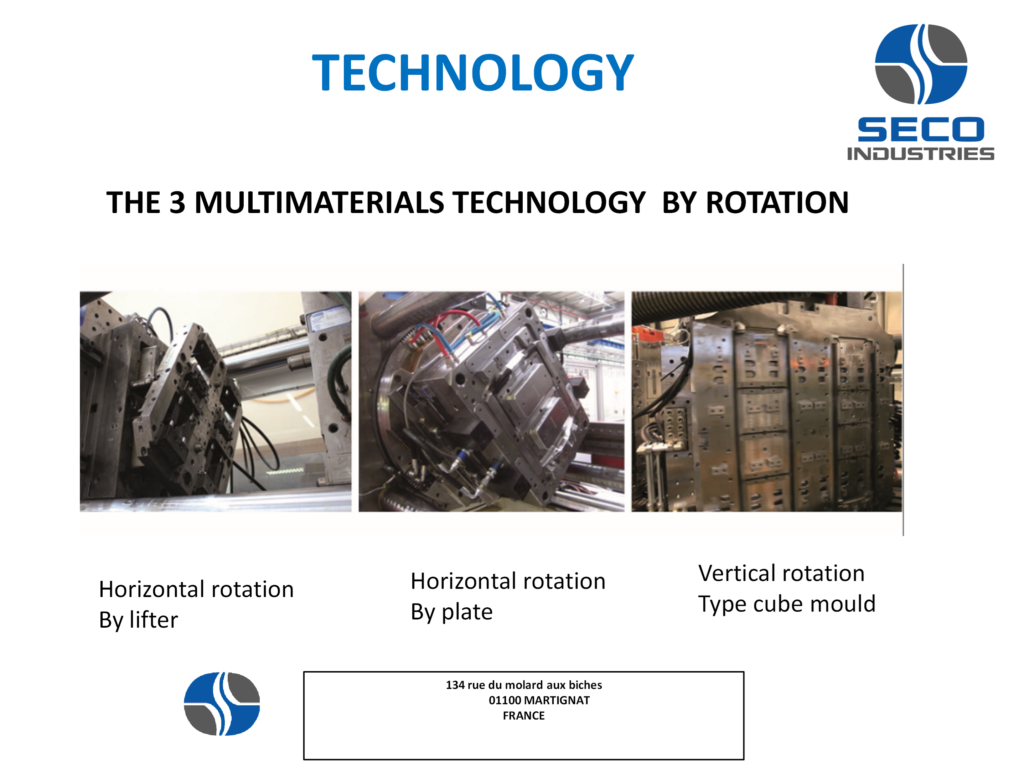

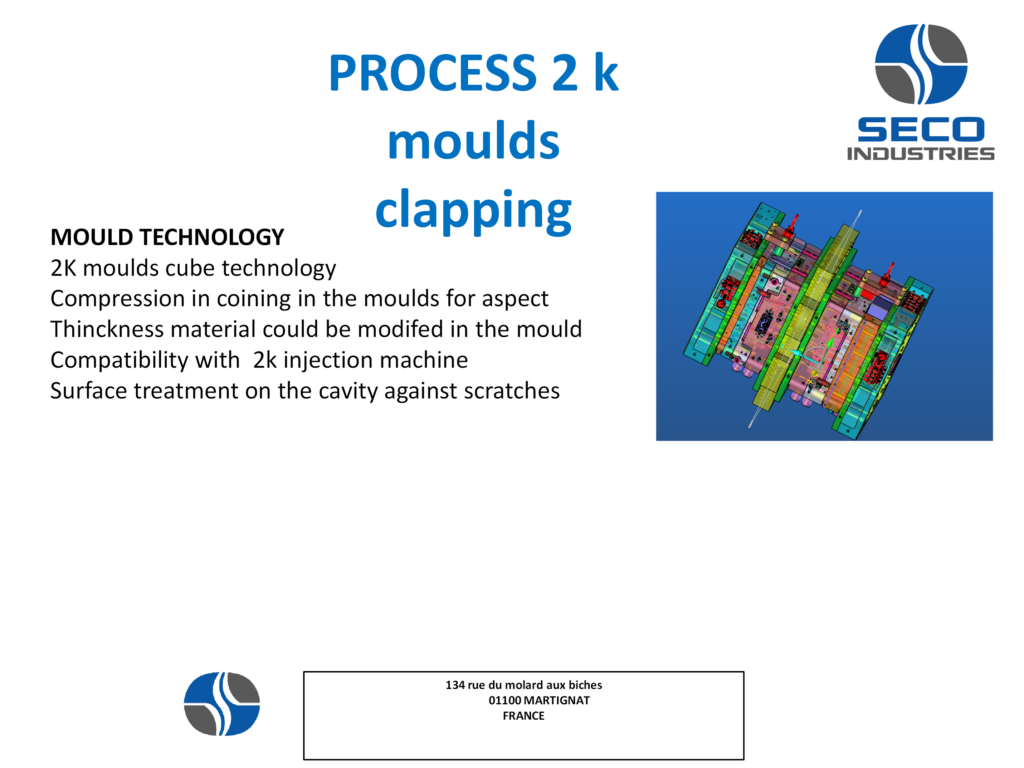

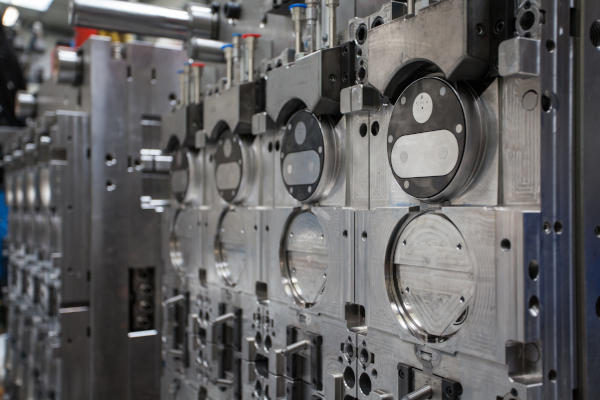

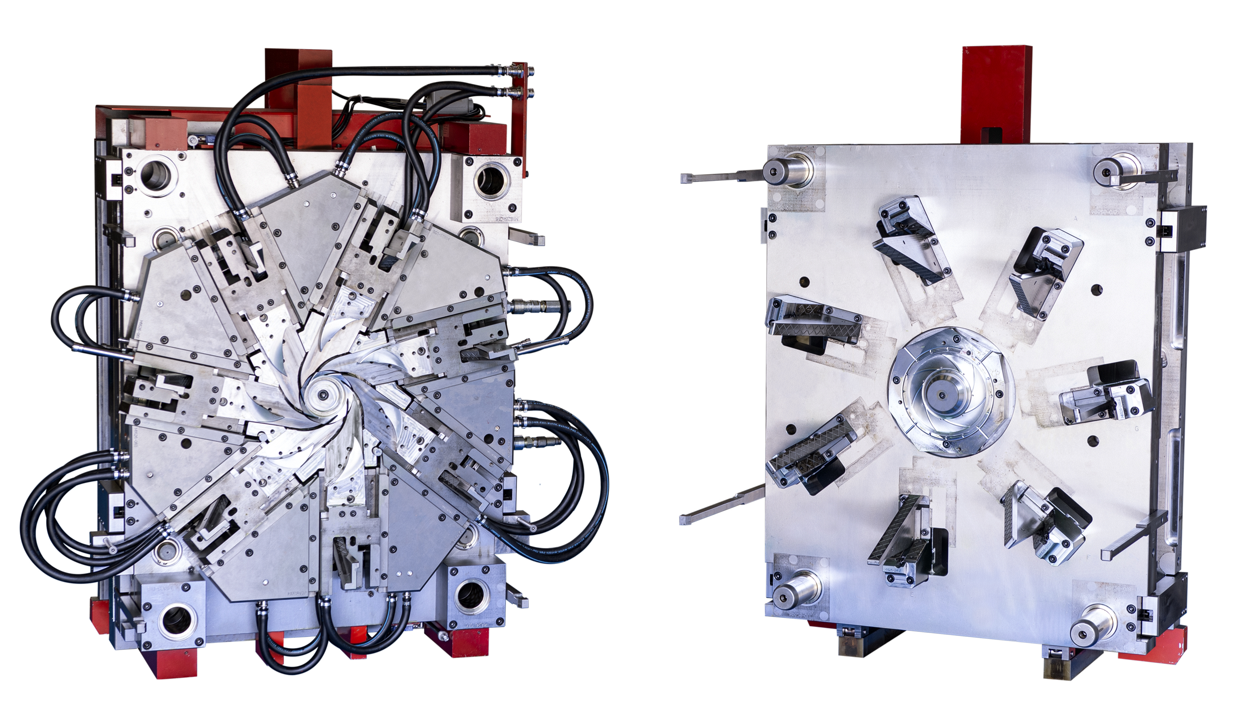

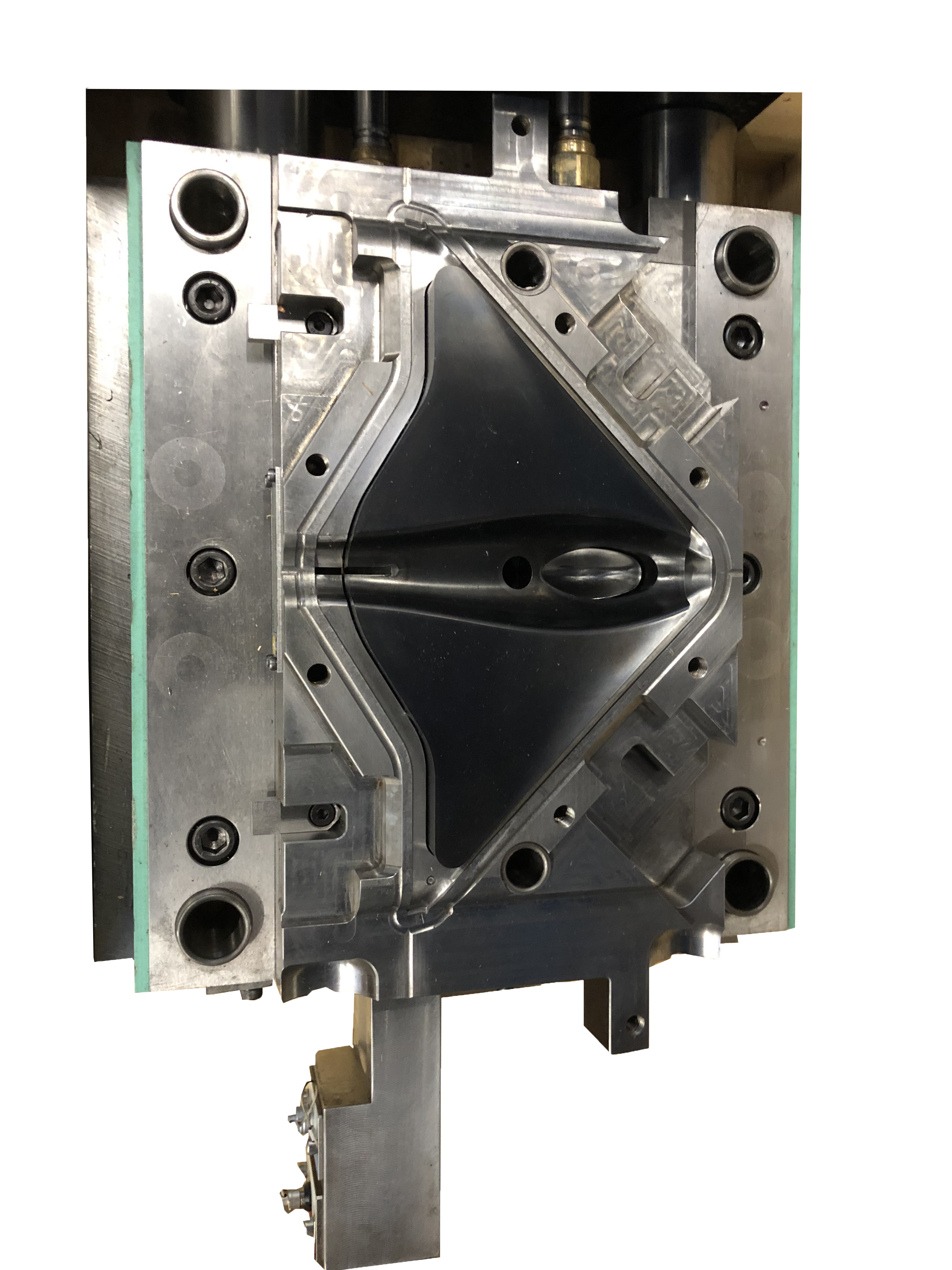

Injection mold

With over 40 years of expertise, we specialize in the design and production of metal molds for thermoplastic injection, delivering complete and customized solutions for your projects.

CONTACT US

E-mail : contact@topcleanpackaging.com

Tél. : +33 04 73 80 32 52

5 rue de l’Innovation, 63920 Peschadoires

Website : www.topcleanpackaging.com