A7-7005

#Mould bases # Formaufbauten #Formplatten #Molds #Formen #Moules

about us :

Now part of LAFOURCADE French industrial group, KANTEMIR company is the leading manufacturer of precision plates and frames/bolsters for injection moulds and tools.

With a guaranteed position and dimensional precision within 0.01 mm, Kantemir is your long-term partner for your custom-made mold bases.

Our CAM-R&D cluster ensures off-line programming and reliable machining according to your data.

Each stage of the production is carried out in a temperature-controlled environment, with the latest generation CNC machines.

Our automated production facility operates a computer network that includes tools pre-setting, gun drilling, rough milling, surface grinding, finishing, and wire erosion.

Very tight tolerance machining benefits cavity to cavity interchangeability and provides high added-value at the assembly stage.

Our ISO 9001 continuous quality improvement process guarantees a consistently high level of quality and absolute reliability.

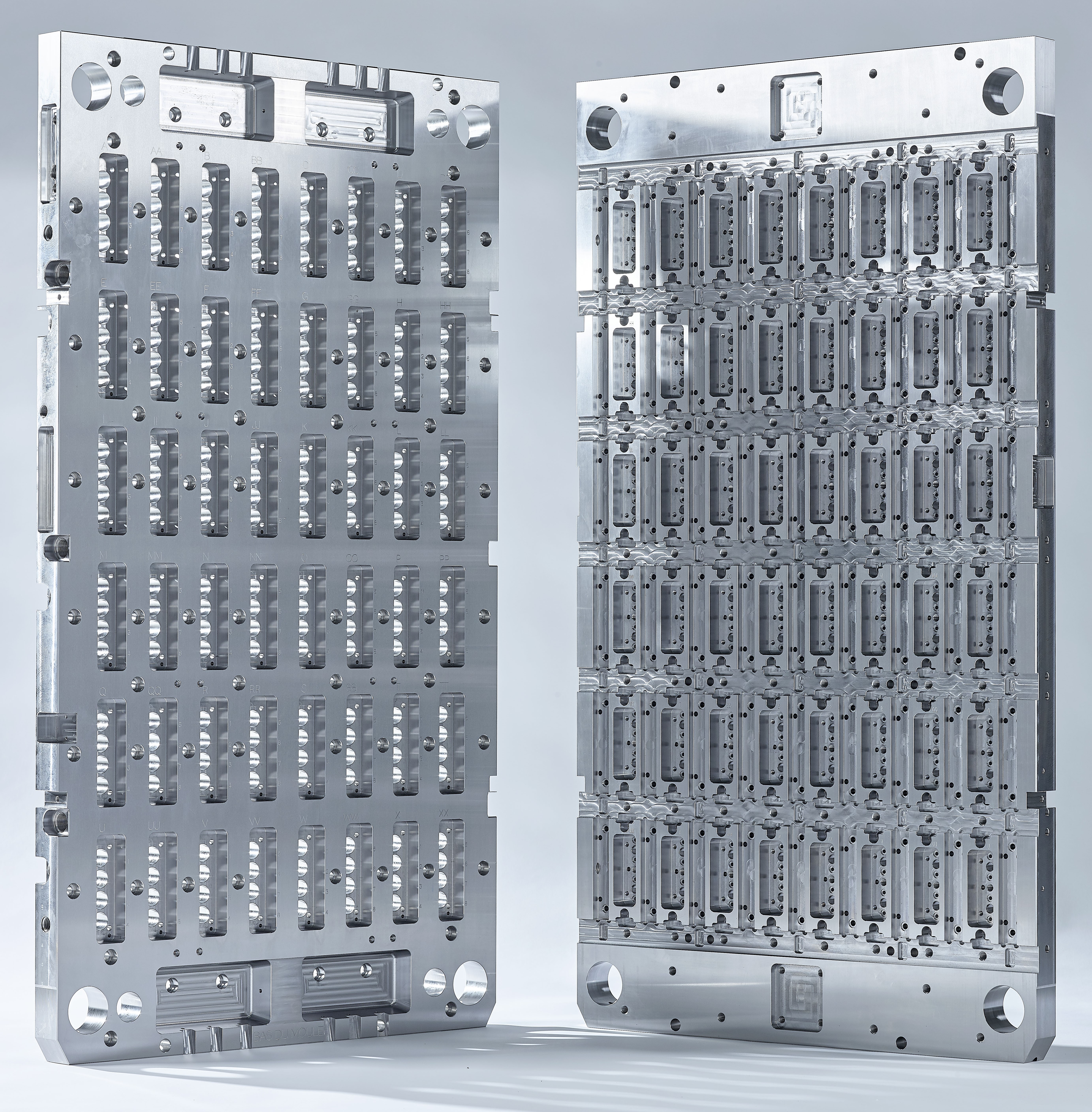

MOULD BASES

Key mold manufacturers rely on KANTEMIR high precise mould plates to optimize their injection moulding cycles and guarantee longer lasting tools with reduced maintenance costs.

Machining in full compliance with your tolerances ensures the perfect interchangeability of mould elements.

We provide consistent 3D CMM reports for each project.

DEEP HOLE DRILLING

Kantemir has 4-axis automated drilling centres with capacities of 2000 x 1350 x 1200 mm.

We can drill individual parts and small or medium series (prismatic parts, round parts, pins…) in straight or inclined positions.

A full machining of the sides is provided.

Drilling of your parts from Ø4 to Ø40, up to 1400 mm depth

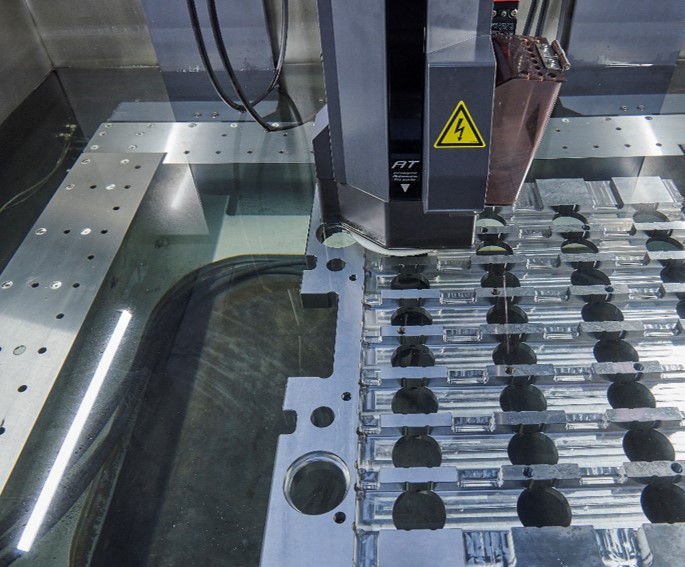

WIRE EROSION

KANTEMIR has the advanced wire erosion technology with travel of 800 x 600 x 510 mm.

Our know how covers all material, from individual parts to series with the maximum precision and reliability.

Parts up to 1150 x 950 x 505 mm

Precision +/- 5µ position; 0,01 mm dimension

CONTACT US

E-mail : info@kantemir.com

Tél. : + 33 (0) 2 97 56 65 21

ZA Mané Craping 56690 LANDEVANT FRANCE

Website : www.kantemir.com