A7-7005

#Injection #Engineering #Medical #Automation #Molding #Precision

about us :

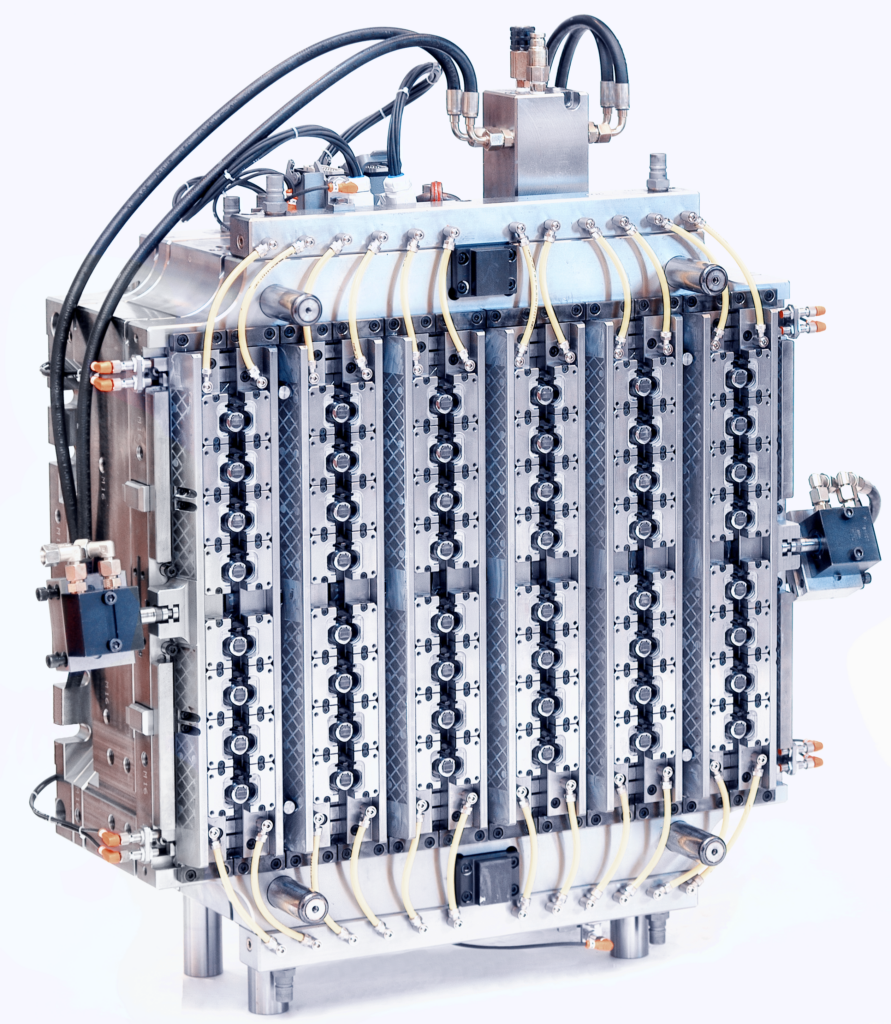

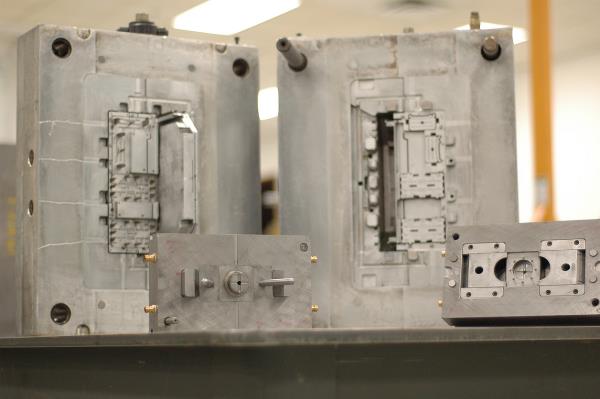

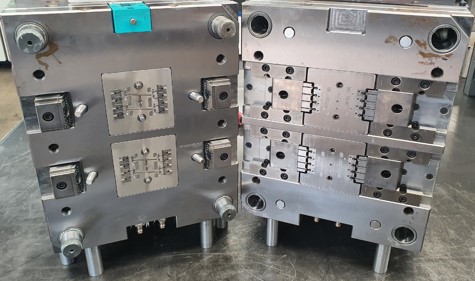

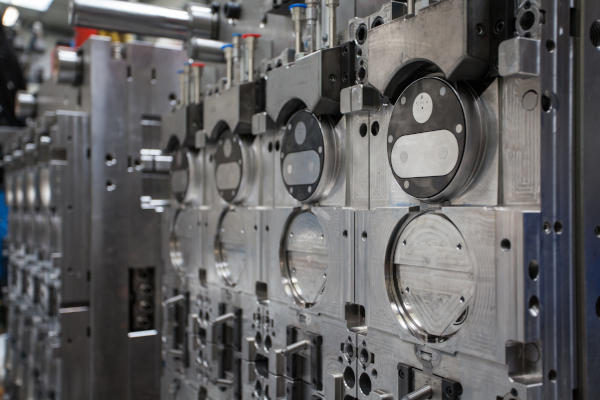

CEMA Technologies is a French group specialized in designing and manufacturing precision multi-cavity molds.

For over 30 years, we produce injection molds for small plastic medical parts industry, such as pump and valve elements for pharmaceuticals, Luer-Locks, pipettes, and well plates for diagnostics.

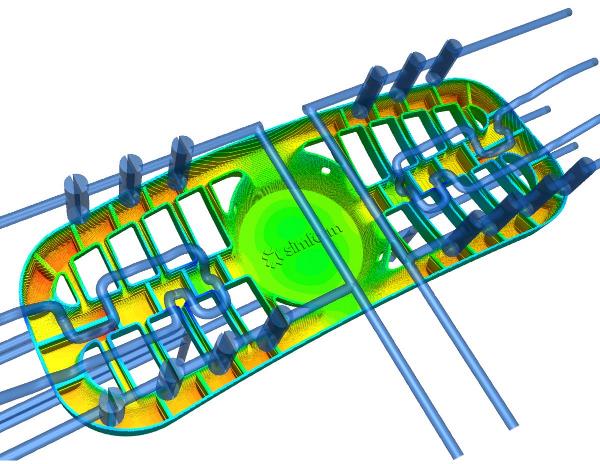

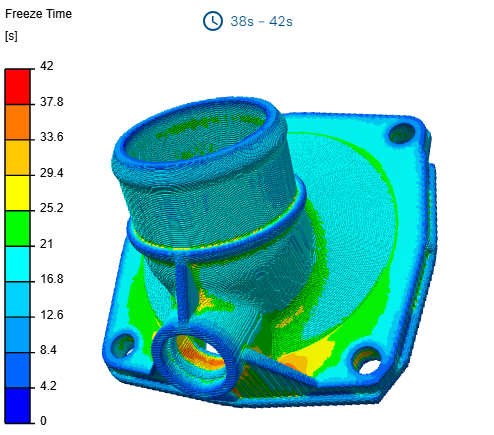

Our services include risk analysis, feasibility studies, real-time production tracking, tooling validation, material consulting and analysis, metrology and tomography, primarily catering to the medical device market.

CEMA Technologies also offers mold repair and upgrades.

Our strong focus on R&D has been a key differentiator, with 7 patents in injection molding.

We provide comprehensive project support, from design to end-of-life, ensuring optimized industrialization.

We collaborate directly with our clients, supporting them from product design to mold servicing. Our expertise ensures high repeatability, reliability, and minimal maintenance, as well as significant energy and material savings.

We are dedicated to helping our clients optimize their industrial processes with sustainable, reliable, and cutting-edge technologies. Our expert team supports them every step of the way, ensuring optimal performance throughout the production cycle.

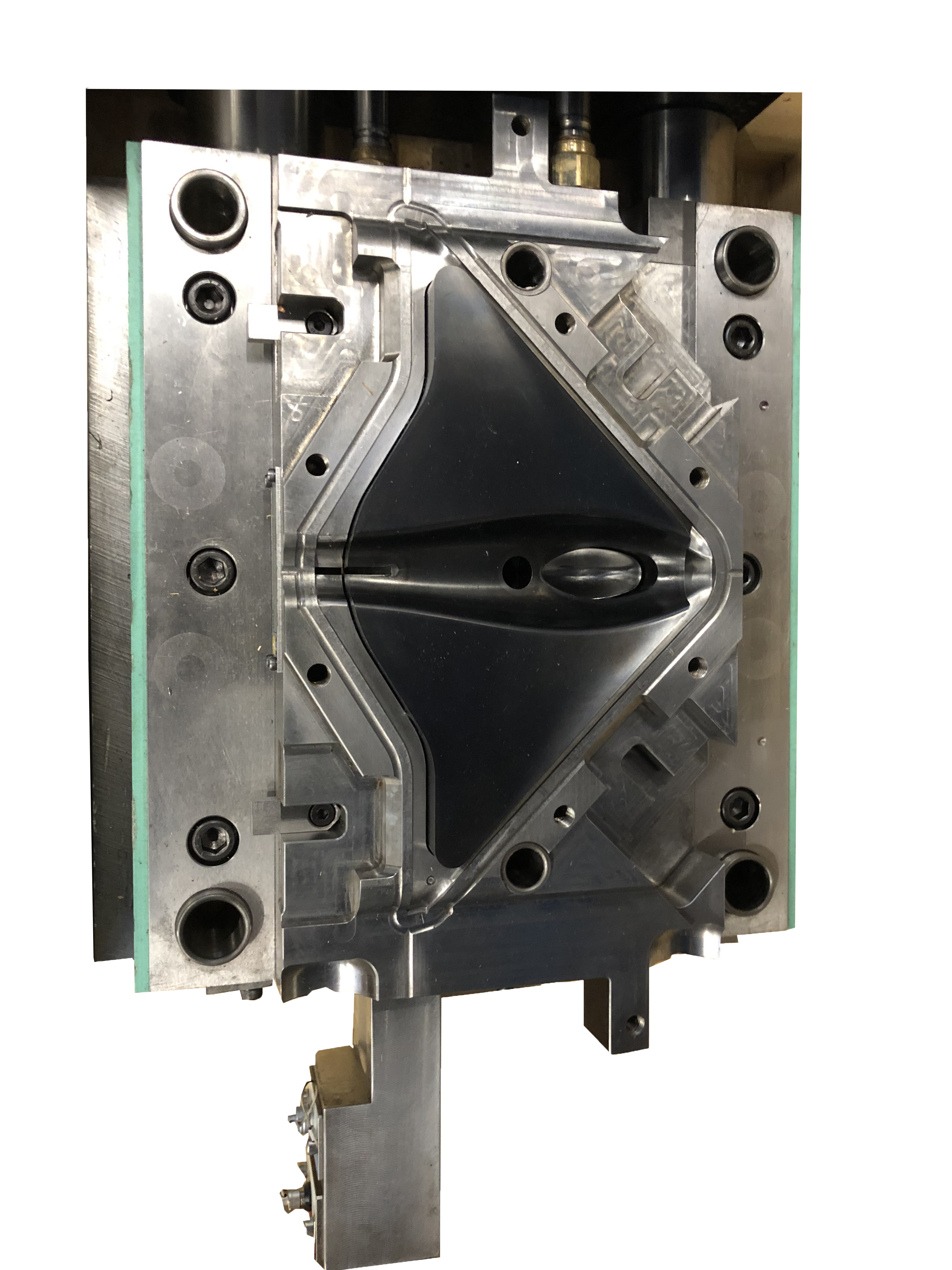

Produit : Molds for Medical Delivery Systems

Service : Design and manufacture of molds for medical delivery systems such as nasal pumps, throat sprays (MDI’s), and DPI inhalers.

Spécificités :

– Steady market growth driven by increasing healthcare needs.

– Suitable for addressing respiratory system inflammation and rhinitis.

– High precision and reliability for medical applications.

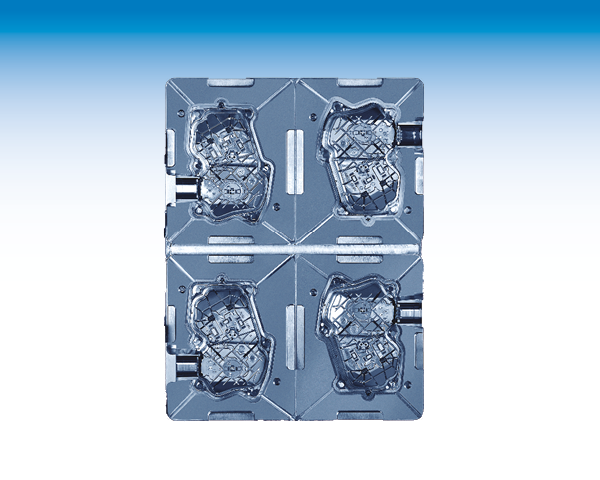

Produit : Molds for Diagnostic Equipment

Service : Development and production of molds for diagnostic consumables like pipette tips, Petri dishes, preparation plates, and cuvettes.

Spécificités :

– Adapts to evolving analysis techniques in biotechnology and microfluidics.

– High-quality, disposable plastic consumables.

– Supports advancements in diagnostic systems.

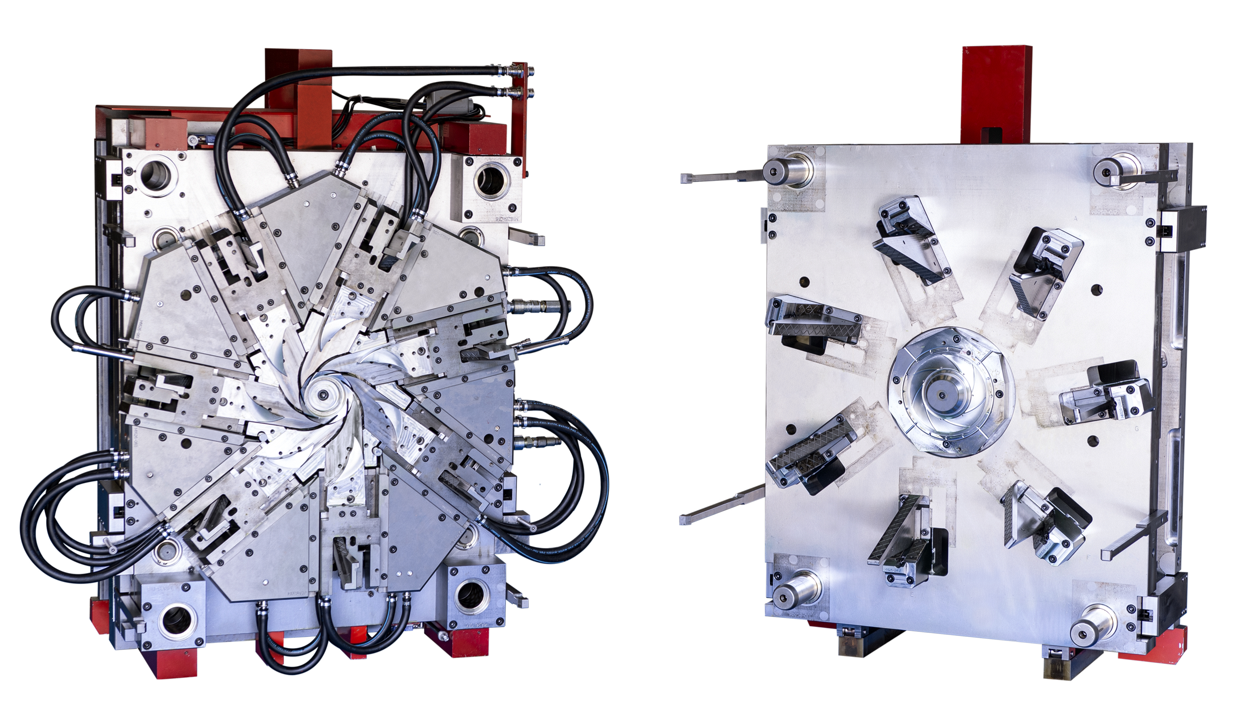

Produit : Molds for Technical Parts

Service : Precision molds for various technical plastic parts including capillary conduits for high-end pens, watch components, dose counter components, and optical components.

Spécificités :

– Custom molds tailored to specific industry requirements.

– High precision and durability for specialized applications.

– Expertise in creating complex technical components.

CONTACT US

E-mail : contact@cema-technologies.fr

Tél : 02 43 75 00 17

24 Rue Alain Gerbault, 72100 Le Mans

Website : www.cema-technologies.fr