A7-7108

#plasticinjectionmolding #prototyping #metalreplacement #industriallapplications #3Dpolymerprinting #lightmobility

about us :

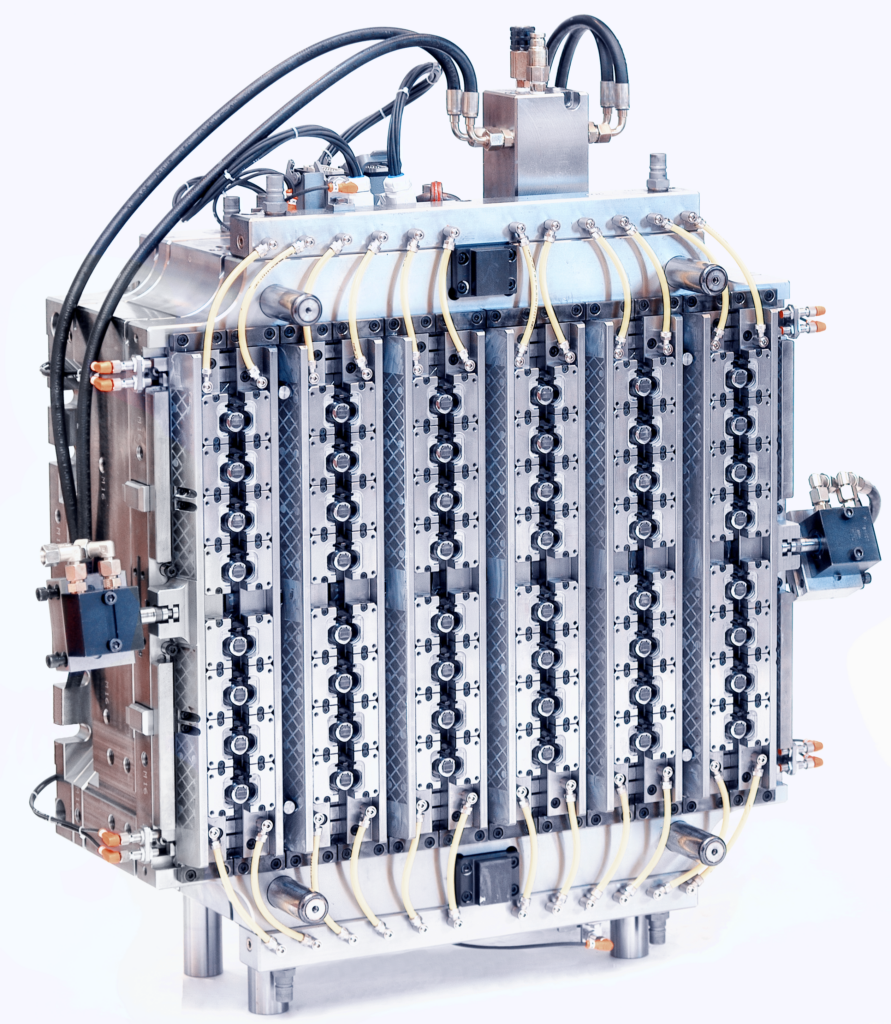

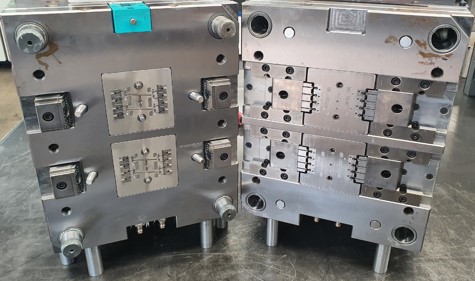

OPS is your innovative partner for plastic injection molding and prototyping – since 1947.

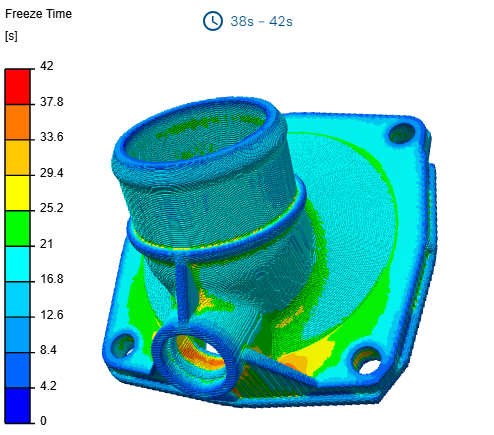

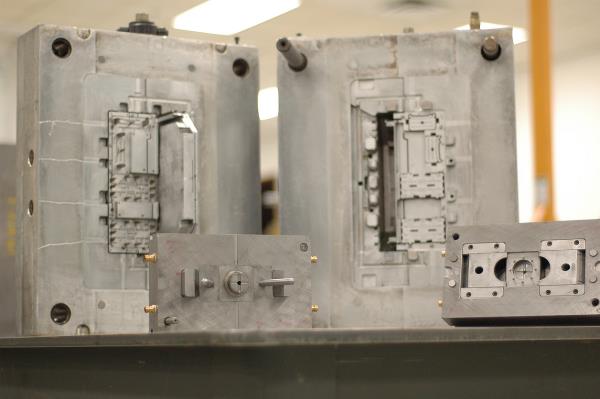

From the initial idea to the production of small and medium series, we provide tailor-made solutions for your industrial applications. With our modern technology and electrical injection machines, we produce precise, high-quality plastic parts.

Our team will support you from the initial idea through to series production, using our in-depth knowledge of tooling to develop your injection molded parts. Innovation, efficiency and cost-consciousness are always at the forefront. Whether you need prototypes, one-offs or fully functional injection molded parts in small batches, we can meet your requirements quickly and reliably.

In addition to traditional injection molding, we use polymer 3D printing to create prototypes and concept models, and even production parts. This combination enables us to realise your projects in a forward-looking and cost-effective way.

Our ISO 9001:2015 certification guarantees the highest quality standards. You can rely on our years of experience and expertise. OPS is your reliable partner for precision and innovation in plastic injection molding.

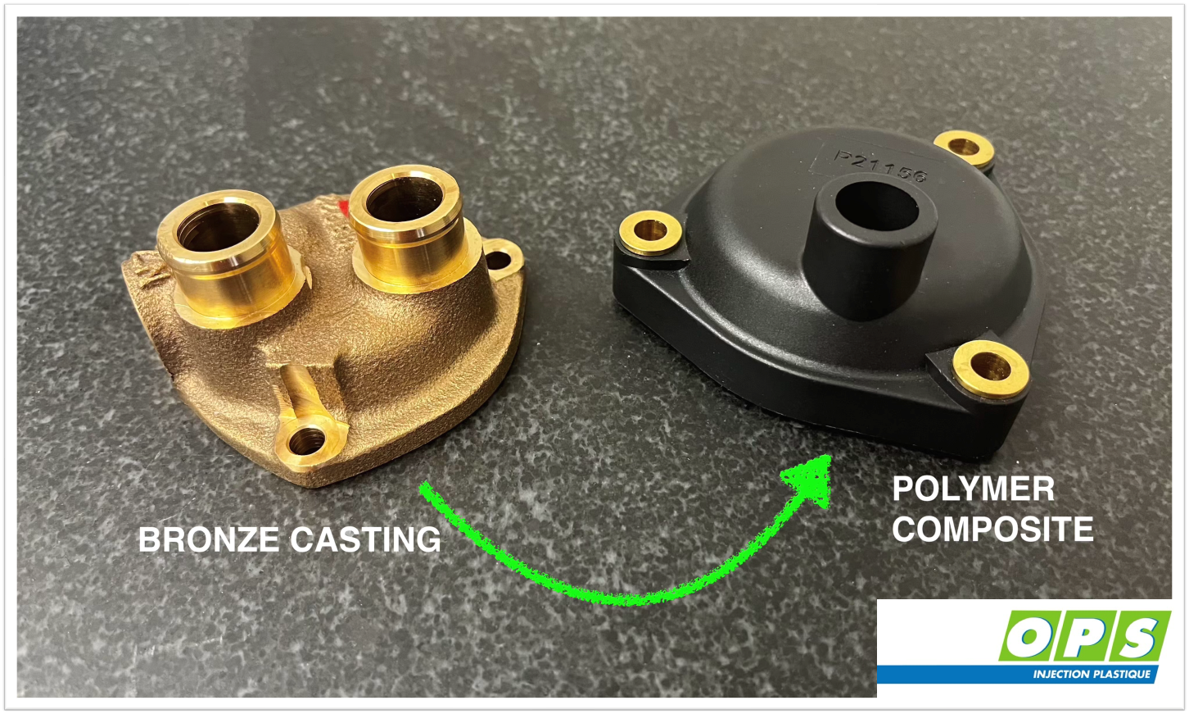

Metal parts lightening

Optimize your mechanical systems by replacing heavy cast parts with our fiber-reinforced composites. Lighten your structural or connecting components by switching from metal to our high-performance polymers reinforced with glass or carbon fibers. Boost efficiency, reduce weight, and enhance performance with advanced material solutions.

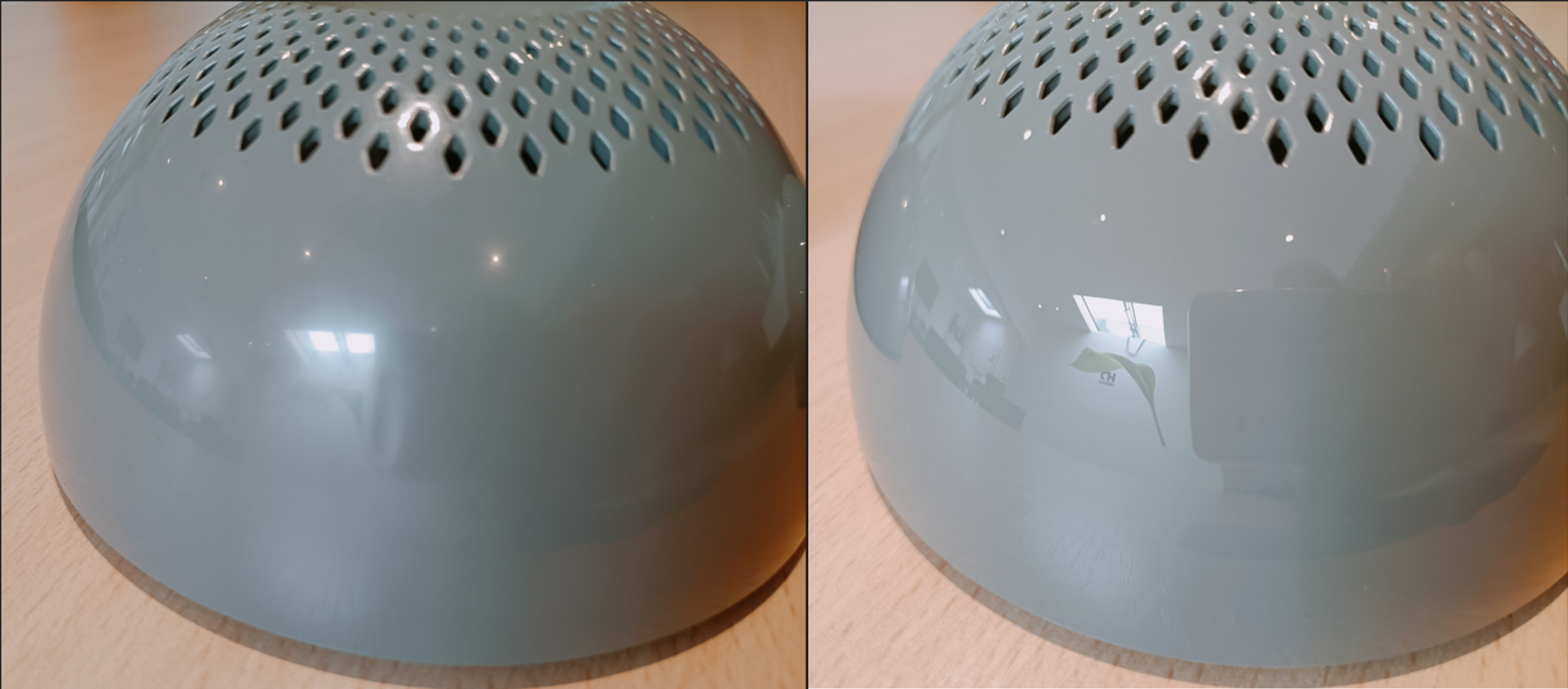

3D polymer printing

Transform your prototyping and series production with 3D polymer printing—reduce lead times and costs by up to 3X. Get your designs faster and at lower costs without compromising on quality. Using various techniques (PA12 SLS, resin SLA, FDM), we adapt to your specific needs and constraints.

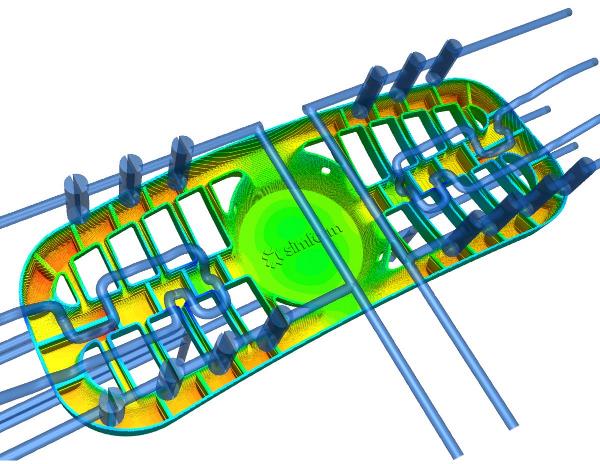

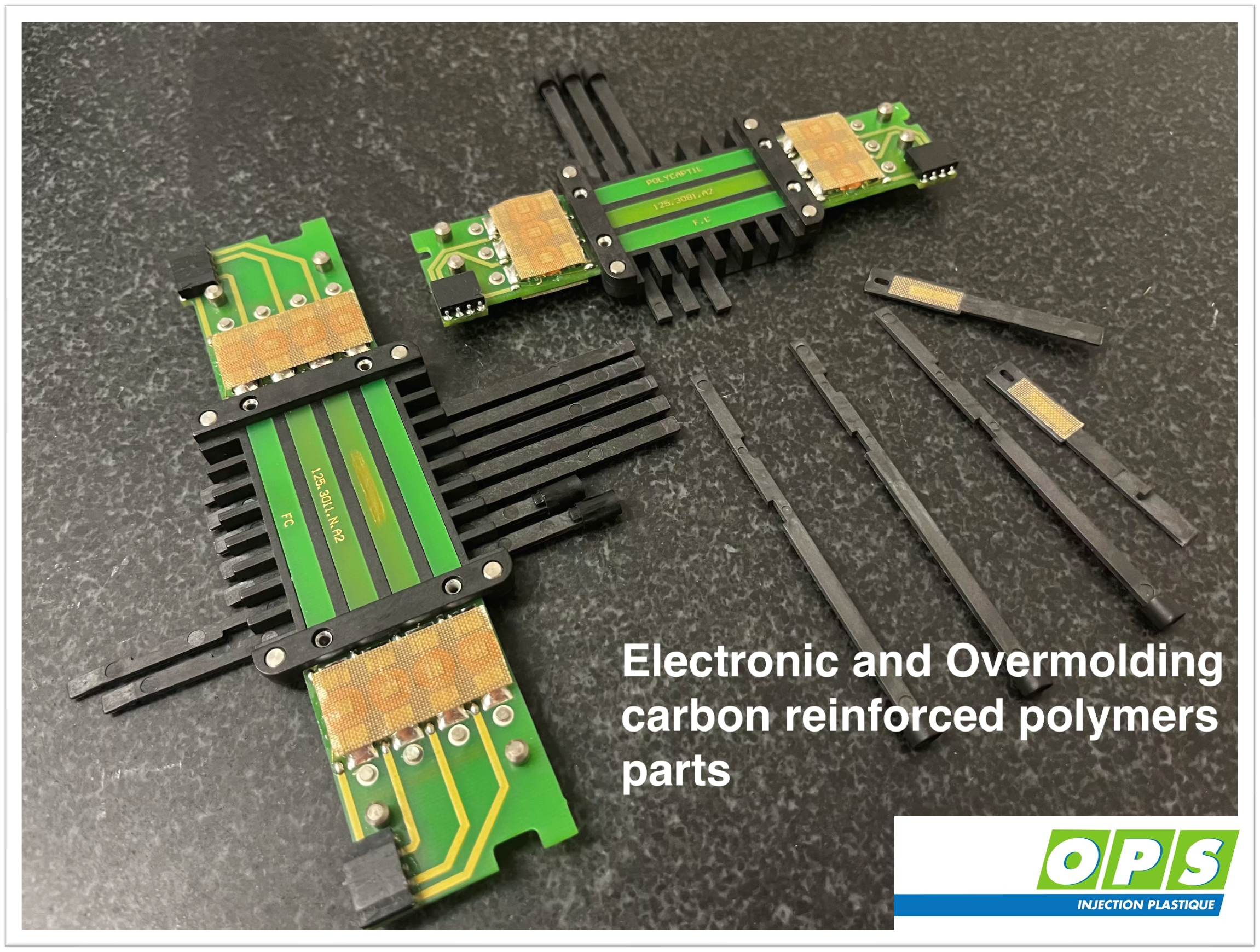

Overmolding of complex technical parts

Enhance your complex technical parts with our expert overmolding solutions. Achieve superior component coupling, compact designs, cost savings, and protection against UV, chemicals, and more. Our process based on elastomer injection ensures excellent sealing, insulation, and reduced noise—ideal for demanding applications.

CONTACT US

E-mail : info@ops-plastique.fr

Tél. : +33 (0)4 74 83 45 67 / +33 (0)4 74 83 32 33

ZA Le Chapelier, 108 Chemin du Marais, 38110 St Jean de Soudain, FRANCE

Website : www.ops-plastique.fr