#water #networks #equipment #performance #preservation

about us :

CLAIRE Group

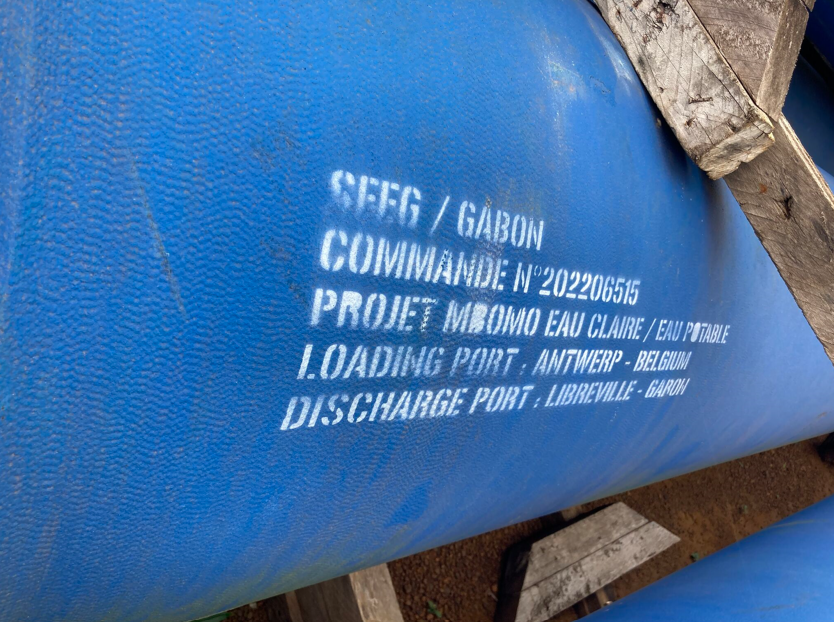

Claire offers a range of equipment for the construction, maintenance and repair of drinking water distribution networks.

Products and systems for diagnostics, monitoring and management complete the offer and improve the performance of water networks.

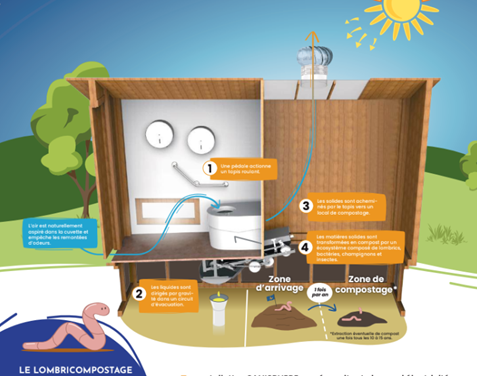

Intervening on the entire water cycle: Natural water, Drinking water, Waste water, Irrigation, Claire group contributes to the preservation of water resources by developing reliable and sustainable solutions.

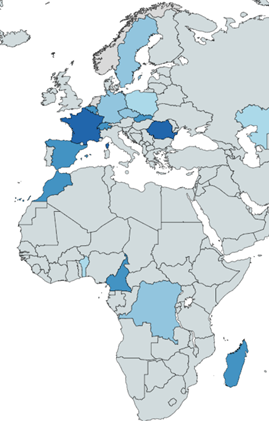

Its clients include several important African water Companies and participates in AFWA events as an affiliate member.

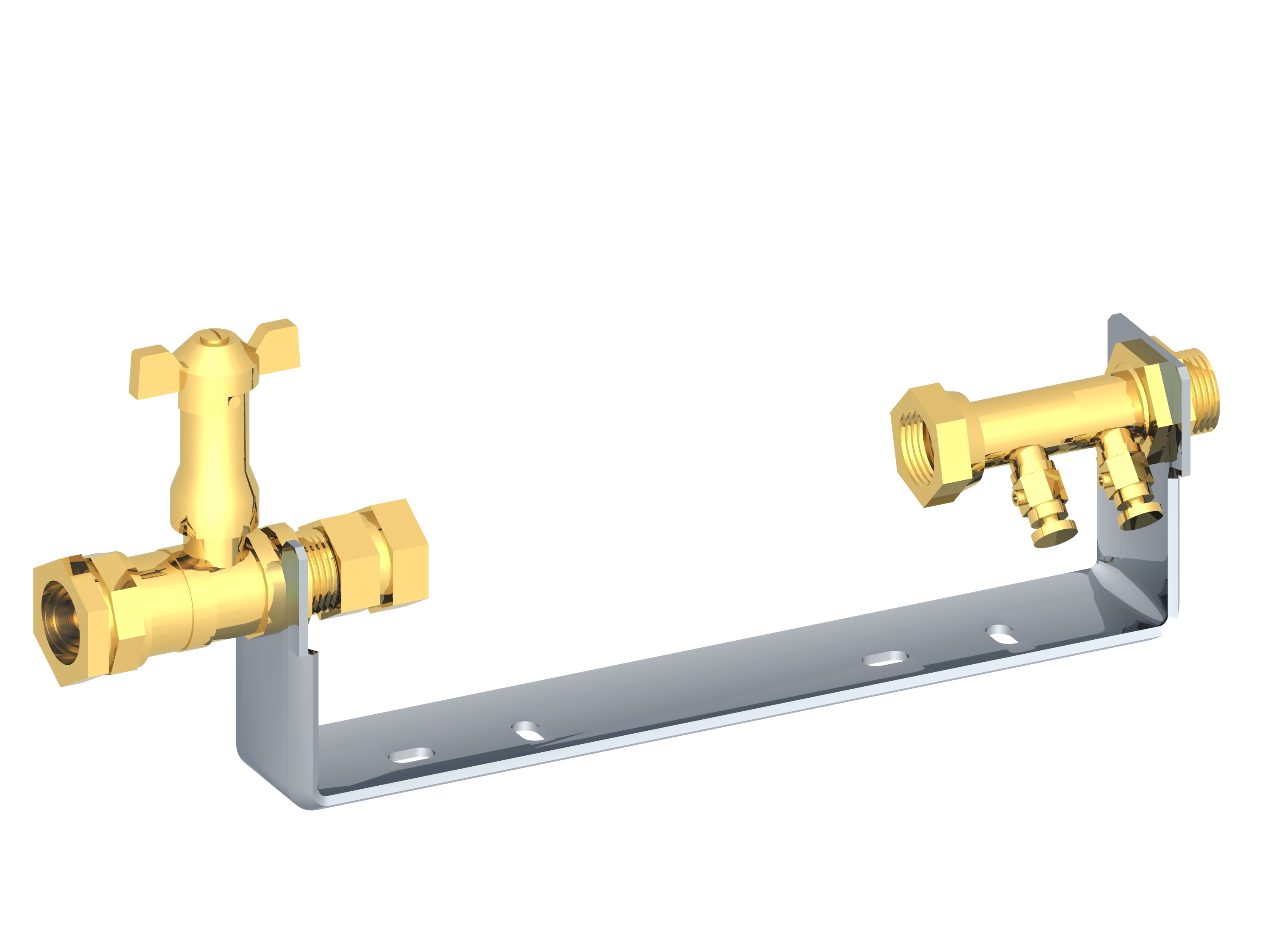

SAINTE-LIZAIGNE specializes in equipments and solutions dedicated to the transfer and distribution of drinking water (from the main pipe to the water meter environment), and offers systems which control and monitor (WAYVE range).

Sainte-lizaigne designs, manufactures in France and sells all the products and solutions dedicated to drinking water connection to water Companies in France and Worldwide

Contact : Marc CORMERY – Tel : +33 (0)6 74 99 74 15 – marc.cormery@sainte-lizaigne.com

EIE (Equipement Industriel Européen) is specialist in intervention solutions without water interruption, manufactures and sells equipment for drilling, derivation and reparation water networks, as well as a dedicated and tailer-made ranges of equipment.

Contact : Marc CORMERY – Tel : +33 (0)6 74 99 74 15 – marc.cormery@sainte-lizaigne.com

ADG (Alpes Diffusion en Gros) industrializes and distributes all products for drinking water equipement. ADG employs advanced technologies and innovating materials in order to supply and complete the range of valves, fittings and accessories for the most demanding professionals.

Contact : Pascal GOMEZ – Tel : +33 (0)6 84 77 03 08 – pascal.gomez@adgvalve.com

IJINUS, manufacturer of autonomous and communicating metrology instruments, develops multi-protocol supervision interfaces intended for drinking water, wastewater, natural water networks : water level sensors (radar and ultrasonic), flowmeter, quality, pressure and water samplers

Contact : Franck MENESPLIER – Tel: +33 (0)6 16 64 17 35 – franck.menesplier@ijinus.fr

F.A.S.T. GmbH designs, develops and manufactures in Germany innovative leak detection and localisation equipment : loggers connected to a tablet or a platform, compact leak pre-locating device, universal solution based on an acoustic and tracer-gas method, multipurpose correlator, leak detection and pipe identification device.

Contact : Edmund RIEHLE – Tel: +49 162 258 8916 – e.riehle@fastgmbh.de

Equipment for water distribution

Water networks diagnosis and monitoring

Leak detection made easy

CONTACT US

Email : marc.cormery@sainte-lizaigne.com

Tél. : +33 (0)6 74 99 74 15 – +33 (0)2 54 04 06 40

28 Boulevard Poissonnière, 75009, PARIS – FRANCE

Website : www.groupe-claire.com