#expertise #water #ductileiron #passion #environment #innovation

about us :

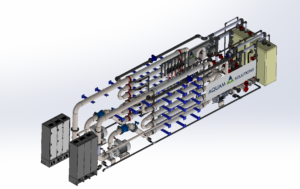

Saint-Gobain PAM Canalisation offers comprehensive ductile iron pipeline solutions for transmission mains and distribution systems serving raw water, drinking water, and sewerage networks. For more than 150 years, Saint-Gobain PAM Canalisation has been a market leader and built a strong global reputation for delivering large scale infrastructure projects. We continually invest time, energy and expertise to create an extensive range of innovative solutions, that are easy to install, simple to join and provide superior value in terms of total life cycle costs for infrastructure owners. We are committed to sustainable and ethical development as outlined in our general principles of conduct and action which apply to all companies within the Saint-Gobain group, regardless of where we conduct business.

Saint-Gobain PAM has been a global leader in protecting ductile iron pipes from external corrosion with its patented BioZinalium® coating, which provides galvanic protection for a long-lasting water infrastructure, offering a practical solution to meet customer needs.

The BioZinalium® coating consists of two layers:

- A layer of zinc-aluminium 85/15 alloy, enriched with copper, is applied with a minimum surface density of 400 g/m². This is achieved by spraying molten metal onto the iron surface using an electric arc spray gun, utilizing ZnAl (Cu) alloy wire.

- A protective layer of Aquacoat® (semi-permeable), a water-based blue acrylic coating with an average thickness of 80 microns, is then applied using a spray gun.

The BioZinalium® coating provides significantly better protection than zinc alone, which has a limited field of use and quickly requires the use of polyethylene sleeving. By eliminating this constraint—since polyethylene sleeving can be fragile during installation and third-party interventions—BioZinalium® ensures the long-term durability of your water infrastructures.

Our technical support services:

Our teams are here to assist you at every stage of your project from initiation to completion and beyond, ensuring the longevity of your infrastructure and protecting your investment.

During the design phase, our technical department can collaborate with engineering consultants to optimize the project design, providing support on ductile iron (DI) mechanical parameters and jointing technologies (both restrained and non-restrained). This ensures the network is tailored to your project’s technical constraints. Additionally, our corrosion experts can conduct soil studies (including resistivity and pH) and water analyses to determine the most suitable external coating and internal lining to guarantee the integrity of your infrastructure while meeting your project’s economic requirements.

Prior to and during project execution, our technical teams can offer on-site training for contractors and water authorities to promote good installation and repair practices.

After project completion, our after-sales service remains available at any time to provide technical documentation and assistance in resolving any potential future issues.

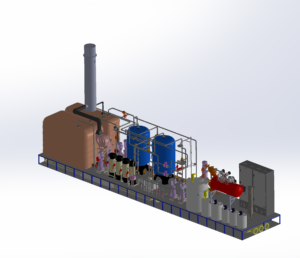

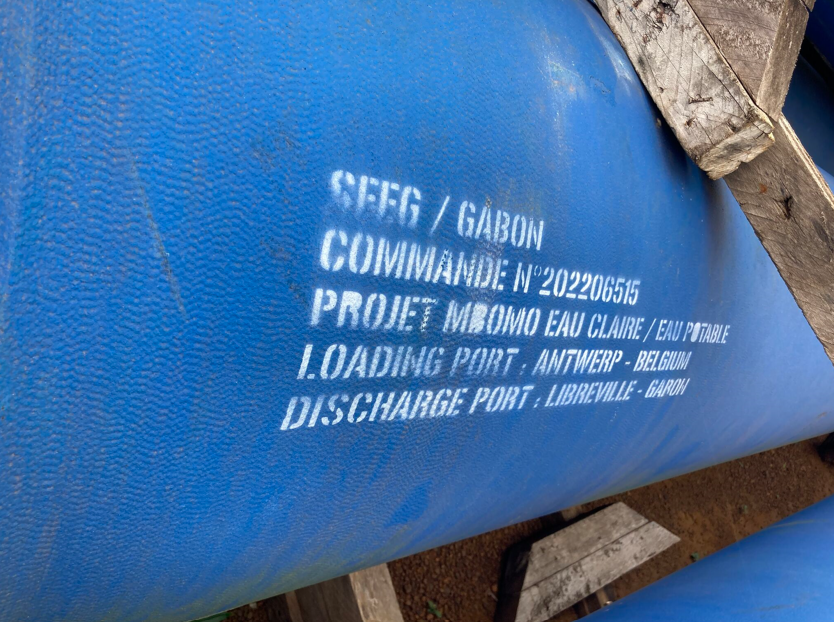

Gabon: Securing Access to Drinking Water for 115,000 Residents :

- The challenge? Strengthening the drinking water supply in Libreville by connecting the new Mbomo water intake to the existing network.

- Our solution? 16 km of DN800 pipes, high-quality fittings, and valves, all installed within tight deadlines.

- The specifics? A demanding context with technical constraints, but also a remarkable human adventure: technical assistance, training of local teams… We overcame all the challenges.

Our responsiveness and the quality of our products made the difference. We supported our client from A to Z, from delivery to commissioning. The first pipes were installed in August 2023, and the project is expected to be completed by early 2025.

CONTACT US

Email : julien.guidat@saint-gobain.com

Tél. : +33 (0)7 86 47 29 57 – +33 (0)3 83 80 75 08

21 avenue Camille Cavalier, 54700, Pont-à-Mousson – FRANCE

Website : https://www.pamline.com/