Public Toilets Made Simple!

Waterless, Autonomous, Ecological, and respecting human beings.

#Toilets #Waste-To-Value #Ecological-Sanitation

#Waterless #Odorless #Sustainable #Vermicomposting

about us :

Since 1991 SANISPHERE has developed Waterless toilets for the most difficult environment because we are convinced flushing toilets cannot be a long term option for many places in the world. Starting from the Mont Blanc, our technology has been proven from high mountains and isolated areas in cold climates to cities in tropical zones.

From Toilet of the extreme to Toilets of the future, our R&D and engineering department has been focusing on all needs around public toilets, from users to servicers through builders and public investors, developing elegant solutions made simple and robust appropriate to all contexts.

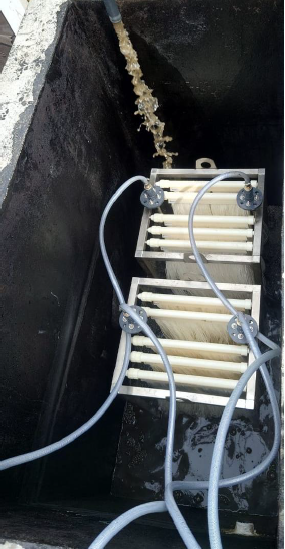

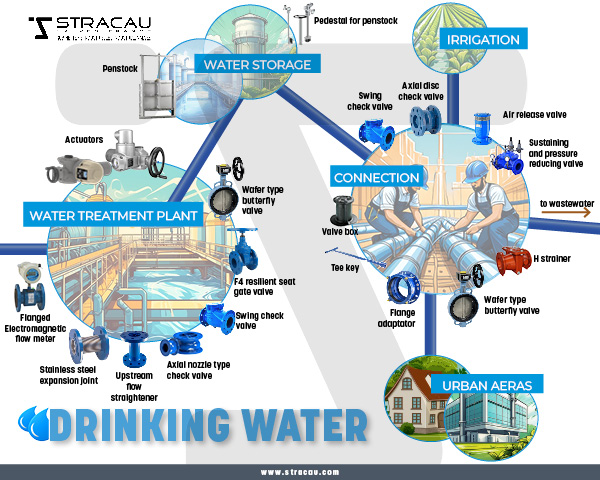

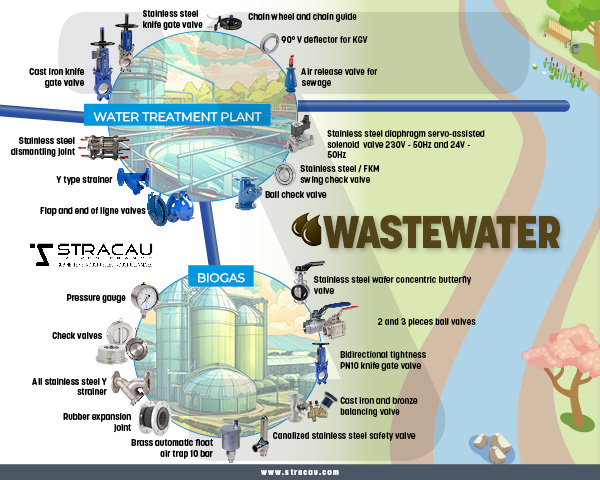

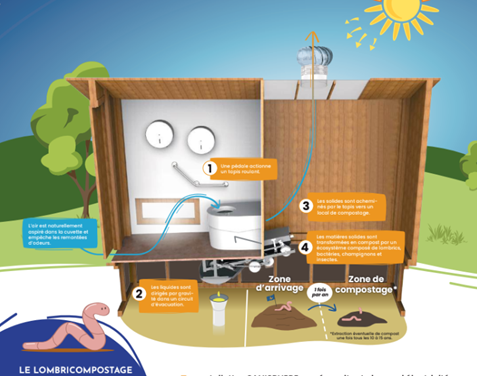

Our patented core technology combines:

- Urine diversion by conveyor to separate effluent reducing smell and facilitating user interaction and treatment.

- Waterless flush to make all the material disappearing from the user

- Ventilation using natural power from Sun and Wind

- Vermicomposting on site reduces by 95% the volume of feces, limiting the emptying and allowing waste to value.

=> No emptying required

=> No sewers connection and no water required

=> Robust against Vandalism and high usage

=> Facilitating resource recovery

We are not just a company but a COOPERATIVE! Sanisphere is owned by its employees, with a strong commitment to build a better world with more consideration for people and the environment, making us a real engaged partner for all your projects! We are also certified ISO9001 proving our ability to serve our customers according to their expectation.

We are a service provider with solutions to your needs, from assessing the public toilet need, to supervising construction or managing the long term servicing. SANISPHERE is with you to make your public toilet project simple. We can partner on tender, support you with the financing of your project, or manage the international logistics of your project, as well as supplying you with the technology.

We are a product supplier of “ready to install” Public toilet Kits, if you are looking for a technology to buy, either standard or with customization, you can directly buy from our international sales team explaining your project and benefiting from our remote support service.

We are a technology provider and manufacturer and will provide you our technology for you to adapt in your own projects. If you are only interested in our core technology you can directly buy it from us and receive our engineers’ advice, and customer service support to facilitate your project.

Our ranges of Products are designed to your specific contexts:

- SaniPop for low frequentation sites, easy to install and maintain

- Saniter for urban context

- Sanimax for highly intense area, like markets or highway roads

- Containerized technology for humanitarian context.

- Custom made buildings, prefabricated or built on site to adapt to your diversity of needs.

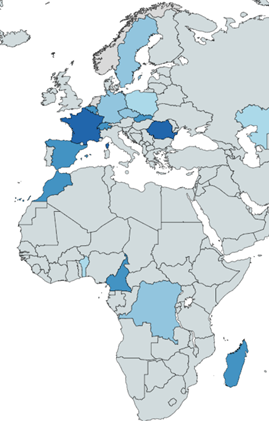

Our References : More than 1300 Working public toilets in 18 Contries

We have worked directly in 7 Countries directly with our team of experts to supply ready to use public toilets.

We work with a network of local partners in 8 countries,

We have sent our technology with a remote support directly to customers in 3 countries

In 2024 we hired an international development team to serve you best, and to facilitate the partnership with local representatives, so if you are interested in working with us, don’t hesitate to contact us.

Looking for Public Toilets in a tourist resort, a city center or a slum? You have high expectations and a difficult environment?

Come to meet us and discover our technology at the AEAA exhibition center, please H5.

CONTACT US

Email : armel@anisphere.fr

Tél. : +33 (0)6 78 89 42 30

154 Allée des Rassades, 26110, Nyons – FRANCE

Website : https://sanisphere-fr.com