M

#Welding #Automotive #Thermo plastics welding #Plastic welding #Infrared welding #Laser welding

about us :

SONIMAT is specialized in the design and manufacture of standard welding machines for thermoplastic parts using infrared, hot platede, laser, rotation and ultrasonic processes. For all types of welding and assembly applications, SONIMAT provides innovative solutions thanks to its mastery of digital technology, offering reliable machines with repeatable processes.

Its expertise also focuses on plastic welding engineering. Our team will support you throughout product development, from feasibility study to series production:

• Co-development of products,

• Assistance to the design office in defining joint drawings,

• Validation of materials,

• Production of prototypes,

• Off-line pre-production welding of parts through to tooling production.

We respond to your problems of industrialisation, design and optimisation of parts.

SONIMAT is also committed to innovation and constant research to offer ever more effective solutions tailored to changes in the plastics processing market. We recently developed a new source for the infrared welding process. It can be used to weld parts with complex geometries and acute angles.

Infrared welding is contactless and therefore creates no pollution. This solution also avoids any change in the colour of the parts and avoids contamination of the heating tool. Finally, it pushes the limits of welding with a hot plate thanks to fusion by focused radiation.

The heat is concentrated only on the welding point. Power consumption is up to 10 times lower than a standard system.

SONIMAT has welding machines in over 40 countries worldwide.

Our team manufactures a wide range of standard infrared welding machines.

We also offer hot plate welders, spin welders and ultrasonic welders to meet most of your applications. Whatever your needs, we have a solution:

• LSW range – Laser welding

• HPW range – Hot plate and infrared welding

• ESW range – Ultrasonic and digital welding presses

• RSW range –spin welding

These solutions come with a wide range of options: rotary table, defective parts tracking system, soundproofed workstation, multi-head system, etc. And to meet your specific needs, our standard product ranges can be fully customised.

SONIMAT solutions are tailored to industrial specifications and requirements. With reliability, repeatability, better control and data backup, your production process is greatly improved.

SONIMAT offers its expertise and know-how to numerous customers in demanding sectors (automotive, medical, consumer goods, etc.).

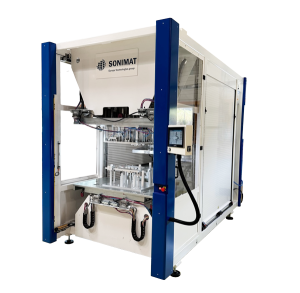

HPW Range – HOT PLATE WELDING AND INFRARED WELDING MACHINES

Our range of HPW presses (hot plate or infrared welding) has been designed to meet the most demanding specifications:

- Fast electrical axis

- Short cycle time

- Repeatability of welds

Our solution is a fully digital press that is accurate and fast accommodating both hot plate and infrared technologies.

GUARANTEED QUALITY

- Hot plate welding technology or infrared welding technology

- Robust mechanical design

- Precision of the brushless axis

- Designed, assembled and controlled by our staff

CHARACTERISTICS

- Perfect mastery of stopping values

- Repeatability of the process

- Mastery of penetration speed

- Optimised productivity gain

LSW range – Laser plastic welding machines

SONIMAT provides an innovative range of laser welding machines for thermoplastic materials.

This laser welding technique uses the transparency of two superimposed materials : one is transparent to the laser energy while the other absorbs it.

The laser beam is focused at the junction of the two parts, passes through the transparent material and melts the absorbent material.

Welding plastics this way creates a solid bond resulting from the rapid cooling of the assembly after the laser beam passes.

GUARANTEED QUALITY

- Laser welding technology

- Robust mechanical design

- Precision of the brushless axis

- Designed, assembled and controlled by our staff

RSW – Dual servo spin welding machines for thermoplastics

Our range of RSW machines (spin welders) has been designed to meet the most demanding specifications:

- Accurate angular orientation and collapse distance

- Reduction of cycle time

- Repeatability of welds

We fulfill those criteria with a dual servo welder.

GUARANTEED QUALITY

- Spin welding technology

- Robust mechanical design

- Precision of the electric axis

- High accuracy of the rotary drive

- Designed, assembled and controlled by our staff

CHARACTERISTICS

- Perfect mastery of stopping values

- Repeatability of the process

- Mastery of penetration speed

- Optimised productivity gain

- Column available as stand alone with connection and eletrical box

CONTACT US

260 Rue Santos Dumont – 01600 Valserhône

E-mail : l.furlani@europetechnologies.com

Tél. : +33 (0) 671 918 120

www.sonimat.com