n

#Supplier #Industry #Technical #Sustainable industry #Industrial solutions

about us :

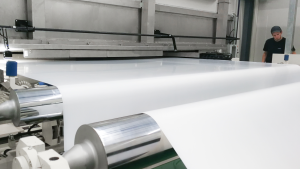

For 40 years, SOCAPS has been the benchmark platform offering manufacturers the service solutions.

INDUSTRIAL OPERATORS :

The know-how of our global community of independent technical experts at the service of your industrial projects, from the simplest to the most complex :

Engineering, Technical audit, Maintenance, New works, Project management, Digitalization …

EQUIPMENT MANUFACTURERS :

The SOCAPS team supports you on a long-term basis in your international development : Design, Assembly, Installation, Commissioning, Maintenance, Recruitment… Field intervention, on your site, your customers site or remotely.

On all our projects, safety and security are our top priorities. Our ISO certified processes regarding QUALITY, SAFETY & ENVIRONNEMENT and our corporate governance commitment complete this approach, which makes SOCAPS a benchmark service provider.

Technical support

- On-site services

- Workshops

- Engineering

Recruitment

- Technicians

- Experts

- Managers

- Directors

Optimisation consulting

- Industrial performance

- Industrial eco-transition

CONTACT US

3 Rue Rollon – 76000 ROUEN

E-mail : julie.adrien@socaps.fr

Tél. : +33 6 43 17 34 86

www.socaps.coop