Booth Hall 2.1 | D115

#biorecycling #innovation #decarbonization #circulareconomy

about us :

Innovation technology

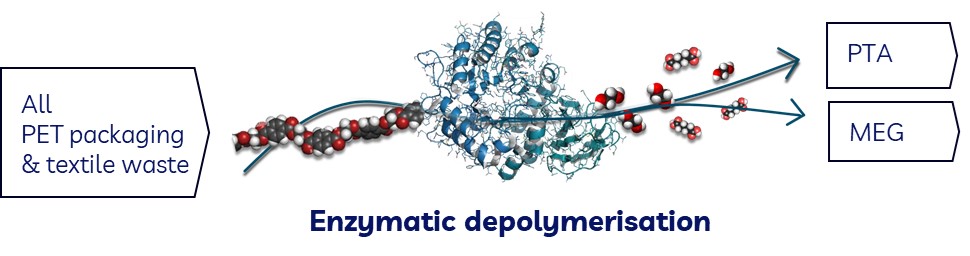

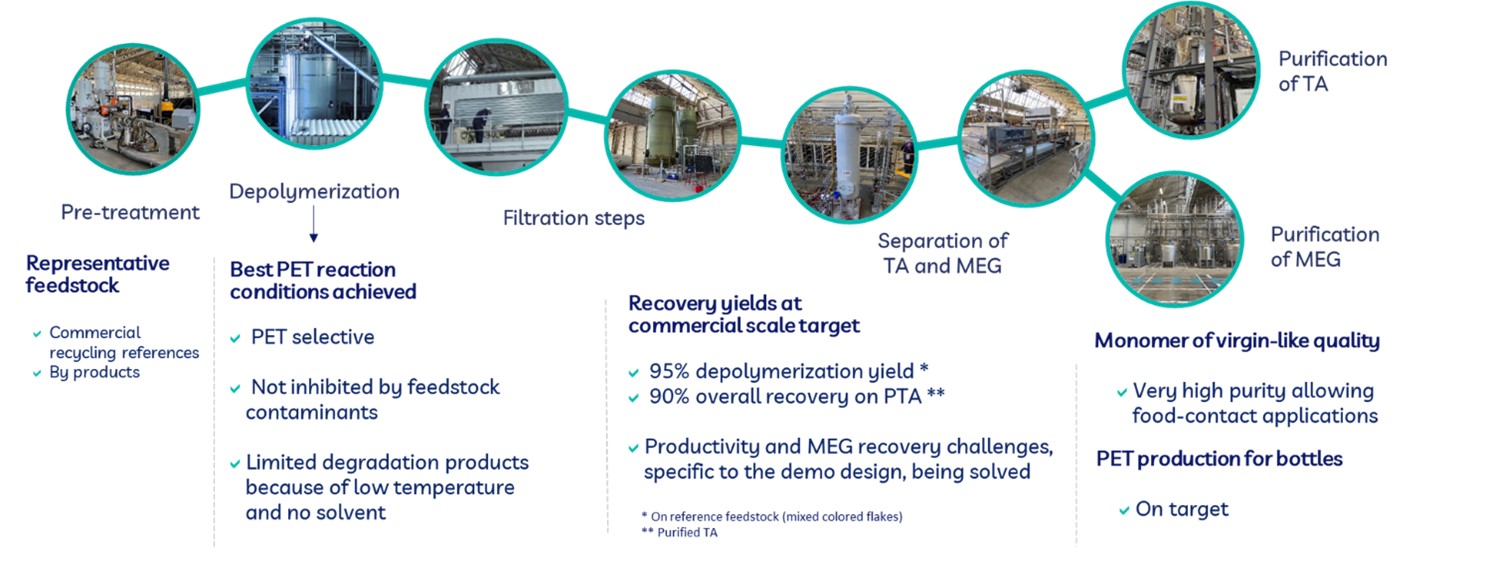

CARBIOS has developed awater-based, solvent-free enzymatic biorecycling process that uses an enzyme specifically capable of depolymerizing PET* at low temperature

*PET (polyethylene terephthalate), the second most produced plastic globally, used for various plastic applications and polyester fibers.

High-end quality monomers and PET content

The CARBIOS process then involves purifying the resulting monomers from the enzymatic depolymerization. The two biorecycled & purified monomers (PTA and MEG*) can eventually be re-polymerized into a recycled PET content with the same quality as the quality of a virgin PET material that would have been obtained from petro-sourced monomers and produced by the petrochemical industry.

*PTA : Purified terephatlique acid; MEG : mono ethylene glycol

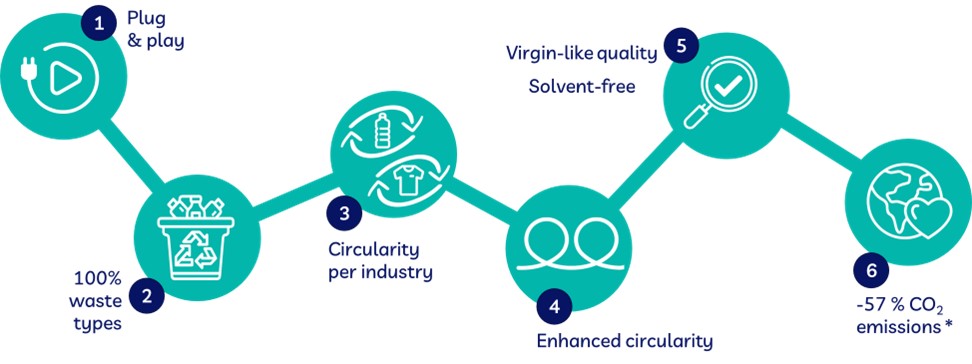

Plug&play

The two monomers produced (PTA and MEG) resulting from CARBIOS’ innovative enzymatic depolymerization and purification processes are identical to petro-sourced monomers. Hence, they can be plugged as fully compatible alternative input materials into existing PET production facilities.

All PET and polyester waste types

CARBIOS innovative biorecycling technology is not limited to clear PET waste. On the contrary it makes it possible to recycle all PET waste types, in resins, films or fibers, including waste that cannot be processed by existing conventional recycling technologies without quality losses, such as food mono or multi-layer trays, colored or opaque PET, and polyester textiles. By taking on a wider range of PET waste types, CARBIOS technology will be able to re-valorize a greater volume of waste and make a significant contribution to reducing our dependence on fossil resources.

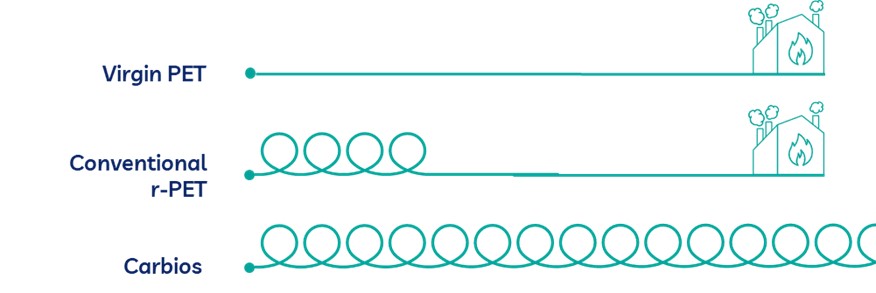

Truly Circular

CARBIOS technology, though a deeper-than-conventional recycling process, can recover the PTA and MEG monomers with the original virgin-like quality. As a consequence, the number of recycling cycles that can be performed is maximized, without any compromises on quality or processability..

Decarbonization

CARBIOS innovative biorecycling technology decouples from the use of fossil resources and significantly contributes to decarbonization. The production of CARBIOS Bio-recycled PET content shows a 57% reduction in CO2 emissions compared to the production of virgin PET*, hence drastically reducing scope 3 emissions integrated in the calculation of the life cycle assessment of any branded product using PET or polyester.

* taking into account diversion of 50% PET waste from a conventional end-of-life. Virgin PET: 2.53kg CO2/kg (cradle to gate), based on ecoinvent 3.8

CARBIOS innovative biorecycling technology is versatile, allowing to recover PTA and MEG mononers from a polyester T-Shirt to make biorecycled PET content with virgin-like qualitative properties used to make a new plastic packaging, and vice versa.

CARBIOS aims to bring the Fiber-to-Fiber circularity of polyester textile at scale

CARBIOS innovative biorecycling technology can re-valorize all types of PET and polyester waste as stand-alone inputs (or in combination) to the enzymatic depolymerization process.

CARBIOS innovative biorecycling technology has been developed and scale up over the last 15 years, in France. It now enjoys an international recognition from a scientific and technology-readyness level.

A demonstration unit at semi-industrial scale is already operating in Clermont Ferrand in France

The construction work of CARBIOS’s first commercial unit at industrial scale has started in Longlaville (France) and will be fully operative from 2026.

CONTACT US

Parc Cataroux – Bât 080 – 8 rue de la Grolière

63100 Clermont-Ferrand, FRANCE

E-mail : xuanlei.zhang@external.carbios.com

Tél. : +86 139 1190 0576

https://www.carbios.com/en/