Booth 10L45

#hotrunnercontrols #moldtemperaturecontrols #productionmonitoringsoftware #valvegatecontrols #processmonitoringsoftware #industrialprocess40

about us :

SISE SAS had a revenue of 14,4 million euros in 2023.

SISE has now 90 employees along with subsidiaries in USA and Germany by a large network of reps and distributors.

SISE has 5 activities with a wide range of products and accessories known worldwide : hot runner temperature controls, mold temperature controls, production monitoring software, valve gate controls and process monitoring software recognised worldwide.

SISE uses a collective intelligence to supply high-tech, innovative, and Advanced solutions 4.0.

The company specializes in applications for the automobile, medical, packaging, electrical, aerotechnical, and chemistry formulation sectors.

SISE develops its position as international specialist in integrated temperature and process control systems for the plastics, composites, chemicals, and calendaring industries.

It does this by developing innovative industrial solutions that improve customers performance.

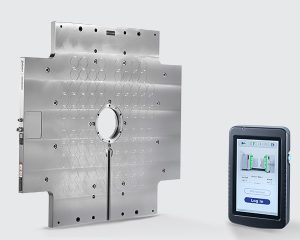

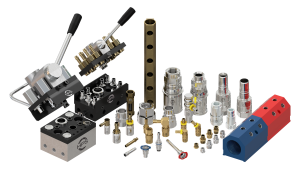

HOT RUNNER MULTI-ZONE CONTROLLER MV3 SERIES

The hot runner controller MV3 Series is able to control up to 336 zones and is available in 6 sizes, XXS, XS, S, M, L, XL. To meet the requirements of different market segments such as packaging, automotive, medical, electrical, MV3 is equipped with power cards of 2.5 A, 15 A, 20 A and 30 A, integrated touch screen control panel of 7”, 10” or 12”.

CYCLADES M.E.S. – SOFTWARE

SISE-designed multilingual «Cyclades M.E.S.» is the ideal tool for small local businesses as well as for large international groups.

–.Real Time Monitoring and Supervision

–.Analysis, Reporting

–.Auto-Adaptative and interactive real-time planning

–.ERP connection (SAP, etc)

–.Machine & Tool maintenance and monitoring

–.Energy Module, SPC Module, Human Ressources Optimization Module, Traceability Module, …EDM module

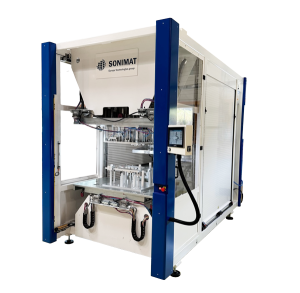

VALVE GATE CONTROLLER: GC SERIES

The GC product line is dedicated to sequential valve gate control.

First, the entry-level GC’Timer control up to 12 pneumatic or hydraulic valve gates, then the GC’Access, up to 18, and finally the GC’TECH, up to 36 gates.

All 3 are equipped with a colour touch screens and VNC link. GC’ACCESS and GC’TECH include new functions such as end of stroke management, multi-material management, curve displays and new programming mode. In addition, they offer traceability of parts produced with part counting, scrap detection and real-time data recording.

CONTACT US

Voie Romaine – Groissiat, 01100 OYONNAX, FRANCE

E-mail : sise@sise-plastics.com

Tél. : +33 (0)4 74 77 34 53 – +33 (0)6 10 34 64 51

www.sise-plastics.com