Booth Hall 2.1 | C112

#Extrusion #Corrugator #Corrugatedpipe #Flatnet #Tubularnet

about us :

CORELCO is a manufacturer of extrusion lines for the production of corrugated pipe and plastic netting focussing on various markets such as:

– Automotive for fluid transfer, part of the battery and engine cooling functions, of the washing line, of the venting line….etc and wiring harness

– Construction for electrical and sanitary conduit

– Infrastructure for double wall cable duct

– Medical for breathing tubes

– Netting

Corelco can supply complete line or line components, standard or adapted to customer’s need for the production range from Ø4mm to Ø250mm with PP-PE-PA-TPE-PVC, mono layer, multi layers and double wall. Corelco supplies after sale service, customer’s training and prototyping.

Automotive market

Vacuum corrugator model EC25M – EC32V – EC50V – EC63V

Production range, Ø4mm to Ø63mm

Variable speed, thickness control

Mould blocks with 5 years warranty

Complete line or line components such as, extrusion head, cooling bath, haul off…etc

HMI (human machine interface) – remote assistance – OPC UA server toward Industry 4.0

Extruders and down-stream equipment integration

Customer’s training and prototyping

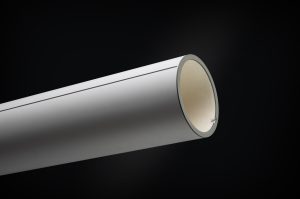

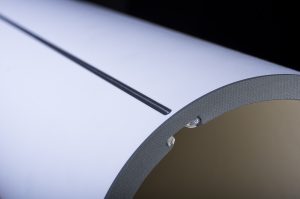

Infrastructure market

Vacuum corrugator model EC63V– EC130V – EC160V – EC260V

Production range, Ø40mm to Ø250mm

Efficient and easy maintenance water cooling

High production speed, up to 30m/min

Complete line or line components such as, extrusion head, cooling bath, haul off…etc

Mould blocks 5 years warranty

HMI (human machine interface) – remote assistance – OPC UA server toward Industry 4.0

Extruders and down-stream equipment integration

Customer’s training and prototyping

Netting market

Flat or tubular, nettings are used in many markets such as, construction, infrastructure, agriculture, paper industry, medical, farming, fishing, filtering……etc

Production range, with or without molecular orientation, 2 meter or Ø250mm

Complete line or line components such as, extrusion head, profile generator, cooling tank, MDO, TDO, winder……etc

High output, up to 300Kg/h

HMI (human machine interface) – remote assistance – OPC UA server toward Industry 4.0

Extruders and down-stream equipment integration

Customer’s training and prototyping

CONTACT US

E-mail : j.vitello@corelco.com

Tél. : +33 (0)3 85 36 10 12 79 96 – +33 (0)6 10 12 79 96

390 Route Dommartin – 01570 Manziat France

www.corelco.com