Booth Hall 2.1 | H112

#Bopp #Bopet #Battery #Biax #Bopa #Bope

about us :

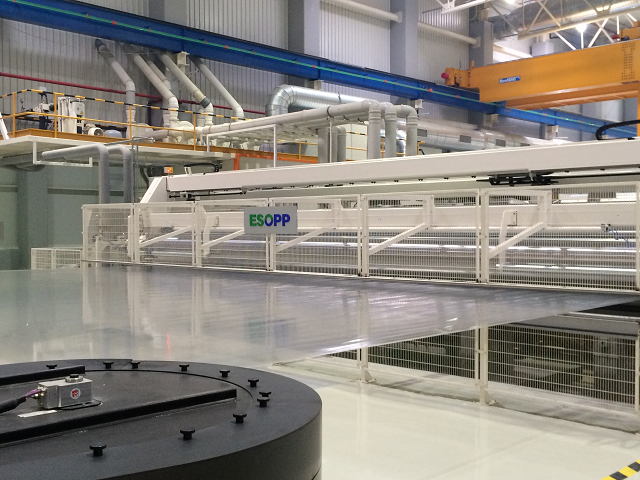

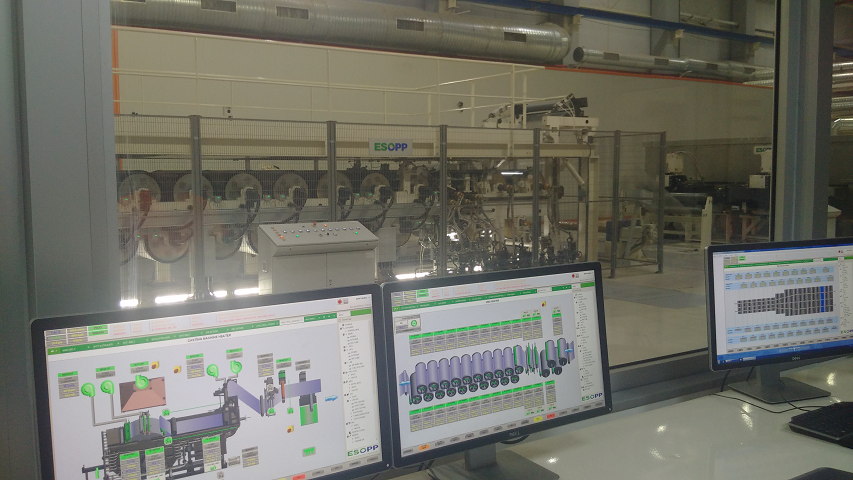

Established in Lyon, France, ESOPP is a distinguished company renowned for its cutting-edge design and manufacturing capabilities. Specializing exclusively in turnkey production lines for molecular bi-oriented polymer systems, ESOPP has been at the forefront of delivering high-quality thin gauge films for both packaging and technical applications. With a design center and factory strategically located in Lyon, a prominent economic and technological hub in East France, ESOPP has emerged as a pioneer in the field, boasting a rich legacy of expertise that spans over five decades since its inception in 1970.

Product Expertise:

ESOPP’s extensive portfolio encompasses a diverse range of stretchable films, including but not limited to:

BO Packaging film: BOPP, BOPE, BOPLA, BIOPP, BOPET, BOPA, BOPS, BOPETG, BOPVC

BO Technical film: BOPP, BOPET, BOPN, BOPI, BOCPI, BOPTFE, BOETFE, BOPVDF, BOPEK, BOPEI

BO Membranes: BOLIBS, BOPP dry, BOPE wet, BOPI, BO NON WOWENS, BOPTFE

These films are meticulously categorized into two distinct areas:

Commodity Film:

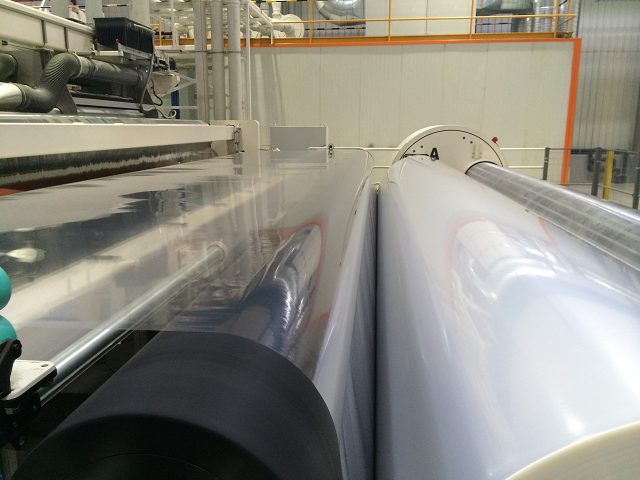

ESOPP’s expertise lies in the development of BOPP machines capable of producing films with varying thicknesses (ranging from 6 μm to 250 μm), winder widths (ranging from 2,000 mm to 12,000 mm), and production speeds of up to 600 m/min

Specialty Film:

ESOPP specializes in providing turnkey production lines for advanced films such as LiBS Separator, capacitor, optical film, and CPI, catering to the demands of high-tech applications.

Patented Technology:

ESOPP’s groundbreaking technology, Flexsim, represents a paradigm shift in simultaneous stretching processes. This patented technology offers an unparalleled range of stretching patterns, enhancing mechanical performance and enabling the production of thinner, bowing-free films at speeds of up to 350 m/min.

Product Offerings:

ESOPP’s product offerings include high-technology BOPP lines capable of producing quality packaging and technical films, characterized by strong seals, excellent hot tack, high barrier properties, and superior transparency.

Additionally, ESOPP’s BOPET film lines deliver superior mechanical properties and high barrier properties, catering to diverse applications in packaging, industrial, electrical, and graphic arts sectors.

Moreover, ESOPP’s BOPA lines produce resilient films with exceptional puncture resistance, tear strength, and high barrier properties, making them ideal for various applications in agriculture, food packaging, medical, and other industries.

Since 2016, ESOPP has successfully delivered over 22 LIBS (Wet & Dry Process) lines, showcasing its proficiency in sequential and simultaneous stretching technologies for battery separator films. ESOPP’s simultaneous LiBS lines offer adjustable MD & TD ratios, ensuring superior film quality without compromising on production efficiency.

ESOPP’s product offerings include high-technology BOPP lines capable of producing quality packaging and technical films, characterized by strong seals, excellent hot tack, high barrier properties, and superior transparency.

ESOPP’s BOPET film lines deliver superior mechanical properties and high barrier properties, catering to diverse applications in packaging, industrial, electrical, and graphic arts sectors.

Since 2016, ESOPP has successfully delivered over 22 LIBS (Wet & Dry Process) lines, showcasing its proficiency in sequential and simultaneous stretching technologies for battery separator films. ESOPP’s simultaneous LiBS lines offer adjustable MD & TD ratios, ensuring superior film quality without compromising on production efficiency.

CONTACT US

24 rue Aristide Berges, 73000 Chambéry

E-mail : t.cornier@esopp.fr

Tél. : +33 (0)4 79 26 51 00 – +33 (0)6 69 08 18 44

www.esopp-group.com