Booth Hall 5.2 | C103

#Hydraulic cylinder #Connector #Codipro #Ironjaw #Molding #Plastic injection

about us :

Since 1990, HPS International has been designing, manufacturing and selling a wide range of hydraulic cylinders.

Recognized worldwide thanks to the famous red color of its cylinders, HPS is today an international company but also a well-known brand, close to its customers.

Present in 28 countries, HPS International has 17 subsidiaries, 11 partners, and 6 manufacturing plants worldwide.

The Engineering Group, located in France, Germany, and Portugal, constantly designs, develops, and improves all HPS products, and brings continuous innovation to their customers.

Indeed, HPS offers a large range of products: block cylinders, round cylinders, tie rods cylinders, and special cylinders. They also offer custom cylinders, specially designed for a very large number of applications such as the Moulds & dies industry, machine building, civil engineering, power plants, oil & gas, etc,

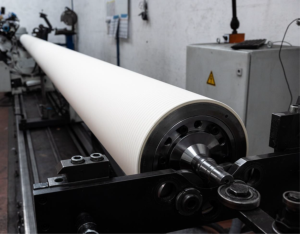

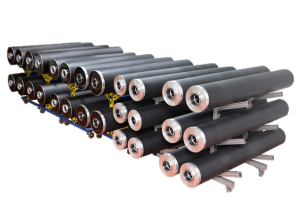

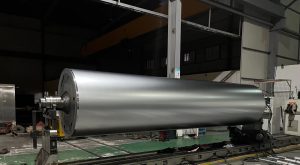

CYLINDERS

HPS production plants can design and manufacture all types of hydraulic cylinders, up to the maximum dimensions of 1 000 mm bore and 10 000 mm stroke. All our hydraulic cylinders are monoblock designed or mechanically assembled. The housing can be block or cylindrical type.

Different types of fixation or oil feeding can be possible.

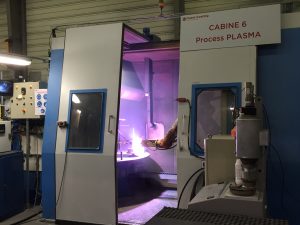

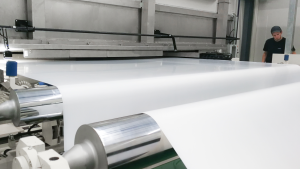

IRONJAW

IronJaw system is the first technology in the world designed to boost the clamping force of plastic injection machines up to +60%. IRON JAW connects to the hydraulic lines of your Injection Molding Machine and it’s operated and piloted by the Injection Molding Machine like a mold core.

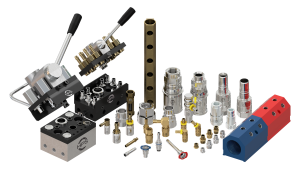

COUPLINGS AND LIFTING RING

HPS manufactures and offers a range of dividers that feed the power of several hydraulic circuits using a single pump. To support the projects of his clients, HPS offers a wide range of water and oil connectors for molds.

HPS proposes a very wide range of lifting rings CODIPRO, with a high CMU, until 50T by ring

CONTACT US

Floor One, Industrial Building NO 2, Furong 7th Rd, Furong Industrial Zone, Shajing St, Bao’an District,

Shenzhen, Guangdong, CHINA – 518125

E-mail : weifeng@hps-china.com

Tél. : +86 755 2917 8531

www.hpsinternational.com