epsilon

#Epsilon #Composite #Carbon #Rollers #Films #Converting

about us :

Epsilon Composite is the world’s leading specialist in the manufacture of carbon fiber-based products, in particular durable, lightweight machine parts and technical rollers for the processing industries. Thanks to their ultra-light yet rigid design, our carbon fiber technical rollers boost machine productivity and production quality. Every year, Epsilon Composite manufactures over 30,000 carbon fiber technical rollers for its customers worldwide, with a comprehensive range covering a wide variety of applications.

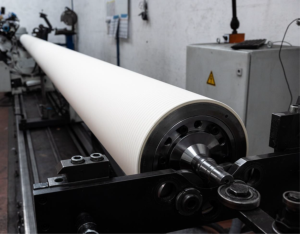

ROLLERS FOR STRETCH FILM PRODUCTION LINE

Solutions for winders and primary slitters

• Tension rollers

• Pick-up rollers

• Rider rollers

• Contact rollers

• Guide rollers

• Dancer rollers

Features

• Diameter up to 600mm

• Length up to 11 500mm

• High stiffness for deflection under 0.04mm / m

• Made by K1 unique patented technology

• Suitable for various applications (optical film, battery and capacitor separator film, packaging film, …)

Surface

• Rubber(EPDM, CR, CSM, …)

• Composite coating

• HardnessSh40~90

References

• Europe and Japan OEMs

• 400 rollers delivered in 2022/2023

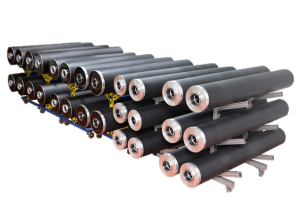

CARBON ROLLERS FOR BLOWN FILM LINE

Solutions for each module

Sizing/Calibrating cage

Collapsing Frame

Turn Bar roller

Guide roller

Winder

Track record

More than 100 000 rollers delivered in 10 years

Dimensions

Phi 40/50/55/60/80/100 made by Pultrusion

L200 ~ 6500

Surface

Polish type (Anti-static)

Journals

Standard Epsilon design for optimized lead-time

Custom design on demand

Balancing

Standard G6,3 at 200m/min (3 planes)

FLEXOGRAPHY CARBON FIBER ADAPTERS

Durable high performance carbon fiber adapters for flexo printing machines

Also known as an intermediate sleeve, intermediate cylinder or interleaf cylinder, the adapter plays a major role in print quality and productivity control

Print tests carried out using adapters of different stiffnesses demonstrate the undeniable influence of stiffness on print quality and productivity.

Only the stiffest adapters (axially and transversely) can meet the requirements of printers:

• Free attenuation/suppression of bouncing

• Reduction of machine downtime

• Reduction of pressure setting times

• Reduction of adjustment times (adhesives, sleeves, plates, etc.)

• Maintain/increase printing speed

CONTACT US

5 Rte d’Hourtin, 33340 Gaillan-en-Médoc

E-mail : naoko.murayama@epsilon-composite.com

Tél. : +33 (0) 5 56 73 47 74 – +81-3-5379-7721

https://www.epsilon-composite.com/en