Hall B3 Booth 3C30B

#Onboard #EmergencyLocatorTransmitter #FlightSafety #IFE #PassengerExperience #Connectivity

about us :

Exail is a leading high-tech industrial group, renowed for its innovative solutions across robotics, maritime, navigation, aerospace and photonics, delivers unrivaled performance, reliability and safety to its civil and defense clients operating in severe environments. From the deep sea to outer space, Exail expands its capabilities with a full range of robust in-house manufactured components, products and systems.

With over 30 years of commitment to clients in the aeronautics sector, Exail has established itself as a trusted partner in the industry. Our expertise lies in designing, developing, manufacturing, and integrating cutting-edge on-board solutions that meet the diverse needs of aerospace organizations worldwide. Whether it is for keeping passengers connected during the flight with our Wireless Access Point solution providing ultra-fast Wi-Fi or ensuring their safety on-board with our emergency locator transmitter solution, Exail is committed to delivering unparalleled comfort and convenience to passengers and crew alike.

Exail’s new generation of Survival Emergency Locator Transmitter (ELT) is a pivotal component engineered to facilitate search and rescue efforts in emergency situations.

Positioned on the aircraft, the ELT is configured to be manually activated in the event of crash, emitting a distress signal that aids rescue teams in pinpointing the location of individuals in need of assistance. It is also activated in case of water immersion. This essential functionality ensures swift and effective response during critical incidents, enhancing the chances of timely assistance and potentially saving lives. Exail’ safety beacon is compliant with latest FAA/EASA lithium battery requirements (DO-227A&(E)TSO-142b)

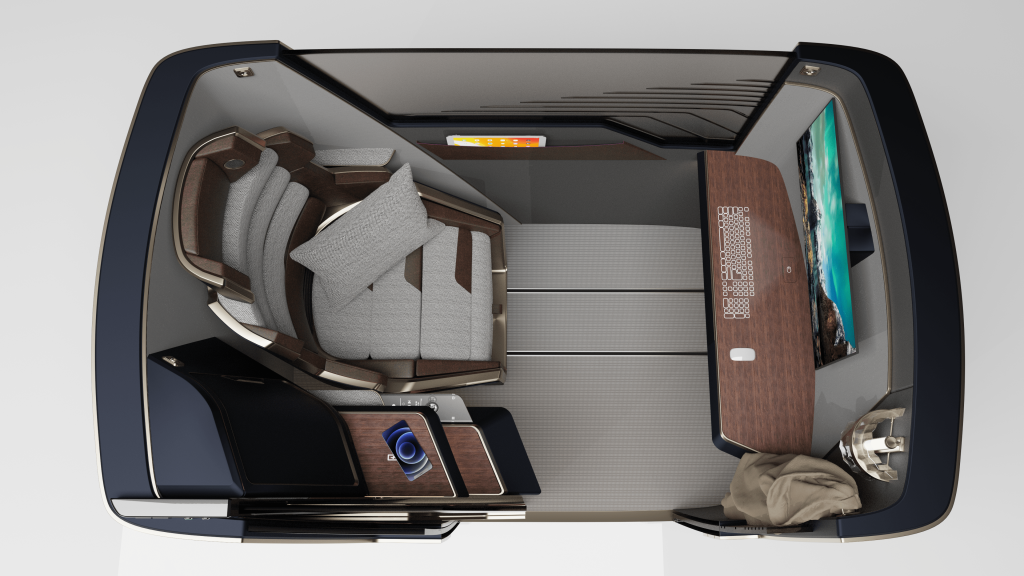

As In-flight entertainment (IFE) emerges as a strategic priority for airlines, performant and highly reliable Wireless Access Points (WAP) have become key solutions.

To answer this operational challenge and deliver enhanced on-board experience, Exail has developed Wizy-Wap, the first WI-FI 6E Wireless Access Point solution.

This technology enables a new frequency band at 6 GHz, delivering up to 1,200 MHz of additional spectrum with wider channels and is equipped with 4 spatial streams. These special features provide powerful connectivity to on-board Wi-Fi and allow passengers to stay connected through their own device to their work, friends and family while on the move.

CONTACT US

6 Imp. Alice Guy ZAC de – 31300 TOULOUSE – FRANCE

E-mail : nisrine.zahir-el-ouadghiri@exail.com

Tél. : +33 (0)5 62 11 17 17

Exail