Hall B6 Booth 6C70D

#Innovation #Engineering #VIP #Interiors #Equipment #HighTechnology

about us :

SOGECLAIR, with over 60 years of expertise, is a supplier of innovative, high added-value solutions for a safer and more sustainable mobility. With over 1,150 employees spread across the globe, in Europe (France, Spain, Germany, UK), North America (Canada, USA), Asia-Pacific (India and Australia), and North Africa (Tunisia), SOGECLAIR offers recognized expertise to cutting-edge sectors such as aerospace, space, automotive, rail, and defense.

SOGECLAIR supports its customers and partners from the design and simulation stages through to the end of the product’s lifetime all along the production chain through to entry into service.

Expertise:

SOGECLAIR DIGITAL ENGINEERING: Expert in mechanical structures, systems installation, interiors, airframe and configuration management.

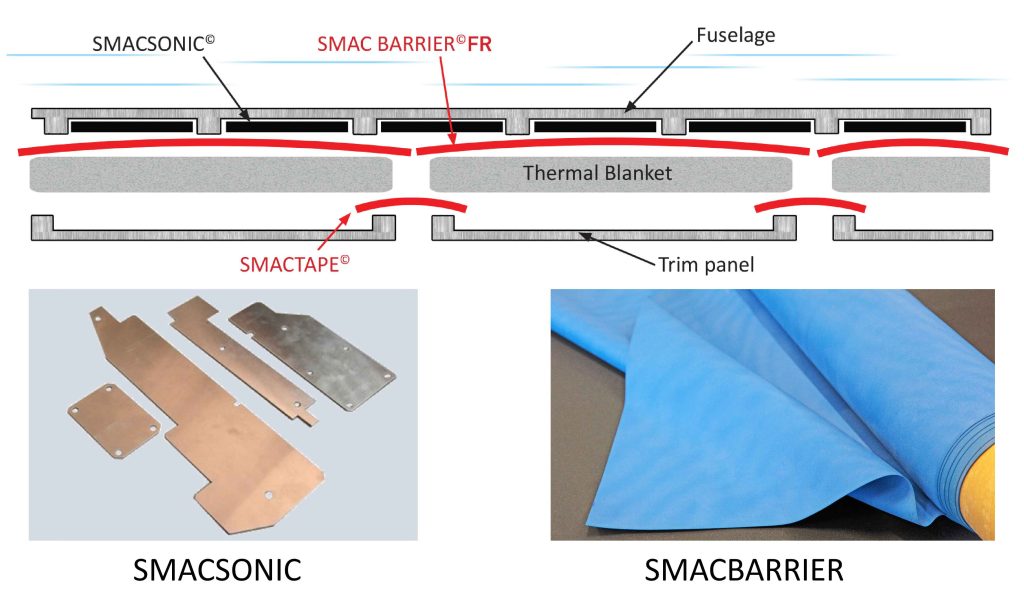

SOGECLAIR EQUIPMENT extends its skills across various sectors, notably in the design and manufacture of structural and interior components for the aerospace industry, highlighting its expertise in innovative materials such as thermoplastics and additive manufacturing. Additionally, SOGECLAIR EQUIPMENT is at the forefront of providing customized solutions in land mobility and robotics

SOGECLAIR SIMULATION : Capitalizing on a diversity of expertise in different forms of simulation, the company offers innovative solutions for the aeronautical sector, with cockpit simulation, and for land-based applications, including rail, automotive and defense simulation.

SOGECLAIR CONSEIL: Leveraging expertise to foster your growth and development through operational consulting, Industry 4.0 implementation, ecodesign practices, and optimization of product and process performance.

Vision & Dedication: Aiming to be a global reference, Sogeclair integrates continual innovation with the development of new materials, ready to meet changing industry demands. Committed to excellence, we ensure quality and consistency, establishing ourselves as a key strategic industry partner. Our agility in specialized areas leads to high-value, customized engineering solutions.

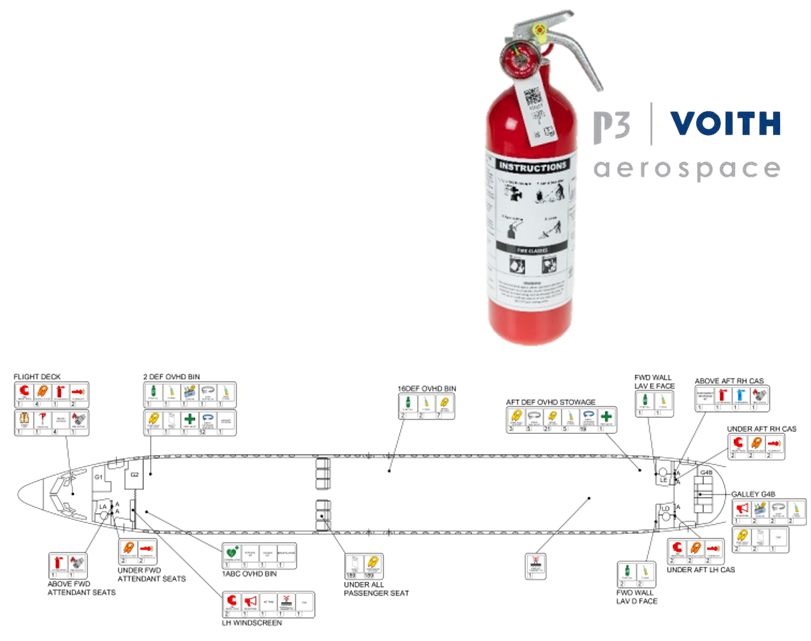

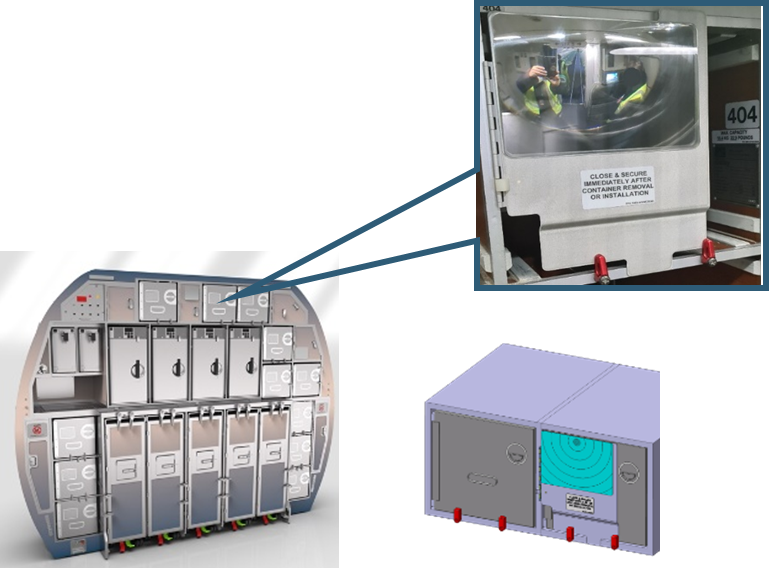

MRO CABIN OFFER: We provide comprehensive cabin modifications, interior upgrades, and system enhancements for the aviation industry. From new galley installations to advanced in-flight entertainment and seating configurations, our solutions boost passenger comfort and aircraft efficiency. Leveraging advanced design and engineering, we deliver turnkey solutions with detailed project planning, certification support, and seamless execution to ensure minimal downtime and maximum value.

CABIN ENGINEERING : Our team specializes in designing and certifying aircraft interior fittings, tailored solutions for both commercial cabins and VIP/VVIP clients. We collaborate closely with clients to define ideal configurations using automated 3D visualization tools. From design to certification, our global expertise covers a range of products including lavatories, galleys, side-ledge tables, and more.

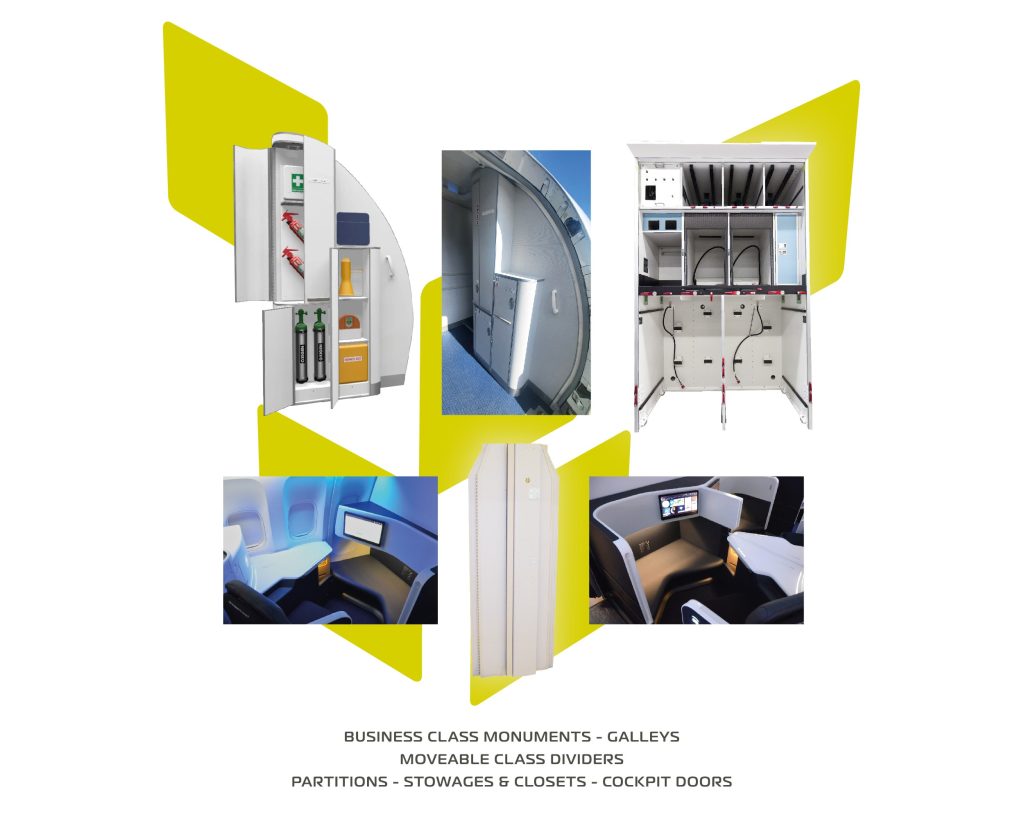

AIRCRAFT INTERIORS : Our teams offer customized solutions covering design, prototypying, and serial manufacturing, for aerospace and rail transport sectors interiors. With expertise in composite materials, plastics, and non-ferrous metals, we provide comprehensive support from design to production, emphasizing quality and safety. We are more particularly recognized for aircraft interiors requiring complex mechanisms and for high-end solution for VIP/VVIP jets.

OUR ECO-RESPONSIBLE COMMITMENTS:

Sogeclair pledges to be a key player in a safer and more sustainable mobility, striving for carbon neutrality. We prioritize inclusivity and societal needs, designing environmentally-conscious solutions for accessible, responsible transport. Our goal is to harmonize technological advancement with ecological stewardship, ensuring a future where progress does not come at the environment’s expense but enhances it for all.

CONTACT US

7 Av. Albert Durand – 31700 Blagnac – FRANCE

E-mail : giuseppe.fiorentino@sogeclair.com

Tél. : +33 (0)7 88 31 79 69

www.sogeclair.com