MRO – Booth 320D

#MRO #SafetySystem #Oxygen #FireSuppression #LifeRaft #ProtectiveBreathingEquipment

about us :

Ateliers Bigata and CEMG Aerosauvetage are both independent EASA / FAA / CAA UK / EMAR FR certified repair station.

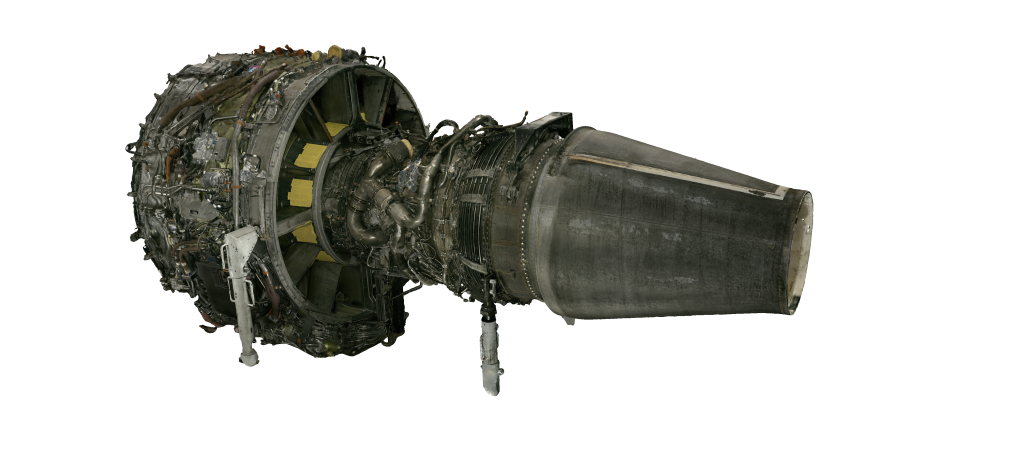

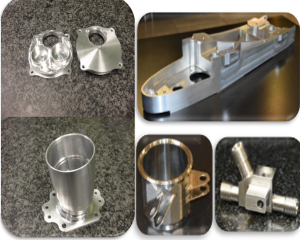

Both provide maintenance services for a wide scope of safety equipment such as Fire Extinguisher (Portable / APU / Engine / Cargo…) Oxygen systems (Crew masks / Cylinders / Regulators), Evacuation Systems (Slide / Raft / Emergency bottles), life raft, life vest, floats and Air Liquide PBE PN 15-40F-80.

Both are US DOT cylinder requalifier (hydrostatic testing) certified and approved by major aircraft manufacturers such as Airbus / Boeing / Bombardier / Embraer / ATR / Dassault / De Havilland Canada, for the maintenance of embedded pressurized equipment.

Our close partnership with all major OEMs make us a reliable repair station for continental Europe, Africa and the Middle East.

From AOG turn-around-time to stock consignment solutions, our team daily supports a large variety of Airlines, MRO centers, OEMs, and brokers.

We hold stock on recurrent rotable PN available for outright sale or exchange, and our Sales division is available 24/7 for part sourcing / brokering / repair management.

May we support you from our home bases in France, our highly reactive and motivated team is looking forward to hearing from your next requirement and to proposing tailor-made solutions.

CONTACT US

Sébastien GAFFET

CEMG Aerosauvetage

Thilbault DALIT General Managers

Ateliers Bigata : 10 rue Jean Baptiste Perrin – ZA MERMOZ – 33320 EYSINES – France

CEMG Aerosauvetage : 345 rue des madeleines – 77100 MAREUIL LES MEAUX – France

E-mail : sebastien.gaffet@bigata.net / thibaut.dalit@cemg.fr

Tél. : +33 (0)5 33 89 49 70 / +33 (0)6 12 80 56 76

+33 (0)1 60 38 20 30 / +33 (0)6 67 83 65 36

https://www.bigata.net/

https://cemg.fr/