Booth 421/520.A

#evaporation #wastewater #watertreatment #reuse #concentration #water

about us :

TMW is a French cleantech company focused on wastewater management, through manufacturing, engineering and consulting activities. The company has developed a plastic evaporator that is able to concentrate very corrosive liquids, and can be used as an effluent concentrator, or as a concentration process step. This technology is based on a proprietary plastic plate heat exchanger technology produced in its facilities in Angers (France): GEPPI. The GEPPI condenses the water evaporated from the liquid flow and transfers the condensing heat to the incoming liquid flow. 80% of the evaporation heat is recycled this way in the evaporator itself. The remaining 20% of energy needed for the evaporation can be collected from the industrial site as waste heat or from the produced streams of distillate and concentrate thanks to a heat pump system. The full solution then reaches very low specific energy consumption.

As the process is performed at atmospheric pressure, and low temperature (on average 40°C lower than boiling point), it is avoiding foaming and fogging phenomena, ensuring high quality distillate. Featuring neither vacuum pump nor heat pump in the evaporation module, it requires very low maintenance and it is very resistant to chemical degradation. TMW has developed 3 evaporation modules, MHD05, MHD2, and MHD5, featuring nominal evaporation capacity of respectively 500 L, 2 m3 and 5 m3 per day. The modules are then assembled in ECOSTILL plants featuring 1 to 10 modules. ECOSTILL plants can be assembled in the wastewater treatment building or it can containerized and delivered as a plug-and-play solution on site.

Around the evaporation modules, TMW has developed a full range of plastic devices and equipment to treat and manage water based flows : filters, pumps, tanks, washing and testing banks, and heat exchangers.

More generally, TMW is supporting its customers from the initial audit through to the implementation of an industrial water treatment and reuse solution. Consulting, testing, piloting and engineering phases are usual business in order to implement the right solution, should it include an evaporation step or not.

TMW brings a unique combination of expertise to the water treatment market:

– plastic machinery and equipment for chemical or sanitary constraints,

– automation and remote monitoring for traceability and process control,

– full support from preliminary design to commissioning,

– water and energy saving solutions.

The ECOSTILL evaporation technology is able to concentrate very corrosive liquids, to reduce effluent volumes or concentrate diluted solutions. 80% of the evaporation heat is recycled in the evaporator itself, 20% can be produced by a dedicated heat pump system, achieving very low specific energy consumption. Performed at atmospheric pressure and 40°C lower than boiling point, it is avoiding foaming and fogging phenomena, ensuring high quality distillate. The evaporation modules are made of plastic, and feature neither vacuum pump nor heat pump, they are very resistant to chemical degradation. 3 module sizes are available: 500 L, 2 m3 and 5 m3/day of evaporation capacity. An ECOSTILL plant includes up to 10 modules, and can be built on site or containerized and delivered as a plug-and-play solution.

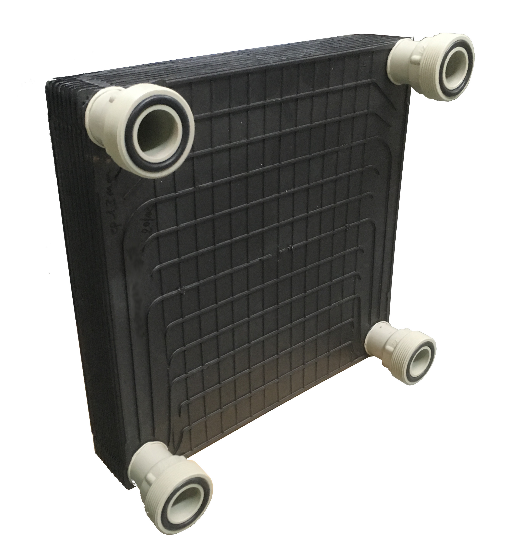

TMW’s GEPPI plastic plate heat exchangers are thermally efficient and chemically highly resistant. They can be made to measure from different plastic materials depending on the application:

-10 to 85°C,

– sheets of around 40 x 40 cm2,

– maximum pressure of 1 bar relative,

– heat transfer capacity up to 240 kW/K/m3,

– resistance to acids, alkalis and salts

– low pressure drops on liquid and gas,

– very compact compared to a tubular plastic heat exchanger,

– very suitable as a condenser,

– low-release materials for pharmaceutical and food applications,

– The G-L heat exchanger can be used in immersion with forced circulation,

– 2″ straight or elbow unions, adjustable number of plates.

CONTACT US

E-mail : gb@tmw-technologies.co

Tél. : +33 (0)2 41 45 15 34 – +33 (0)6 22 01 33 88

9 rue de la Fuye, Parc d’activités de Lanserre, 49610 Les Garennes sur Loire, France

Website: www.tmw-technologies.com