Booth C1.519

#micropollutants #waterquality #biomonitoring #contaminantsofemergingconcern #drinkingwater #wastewater

about us :

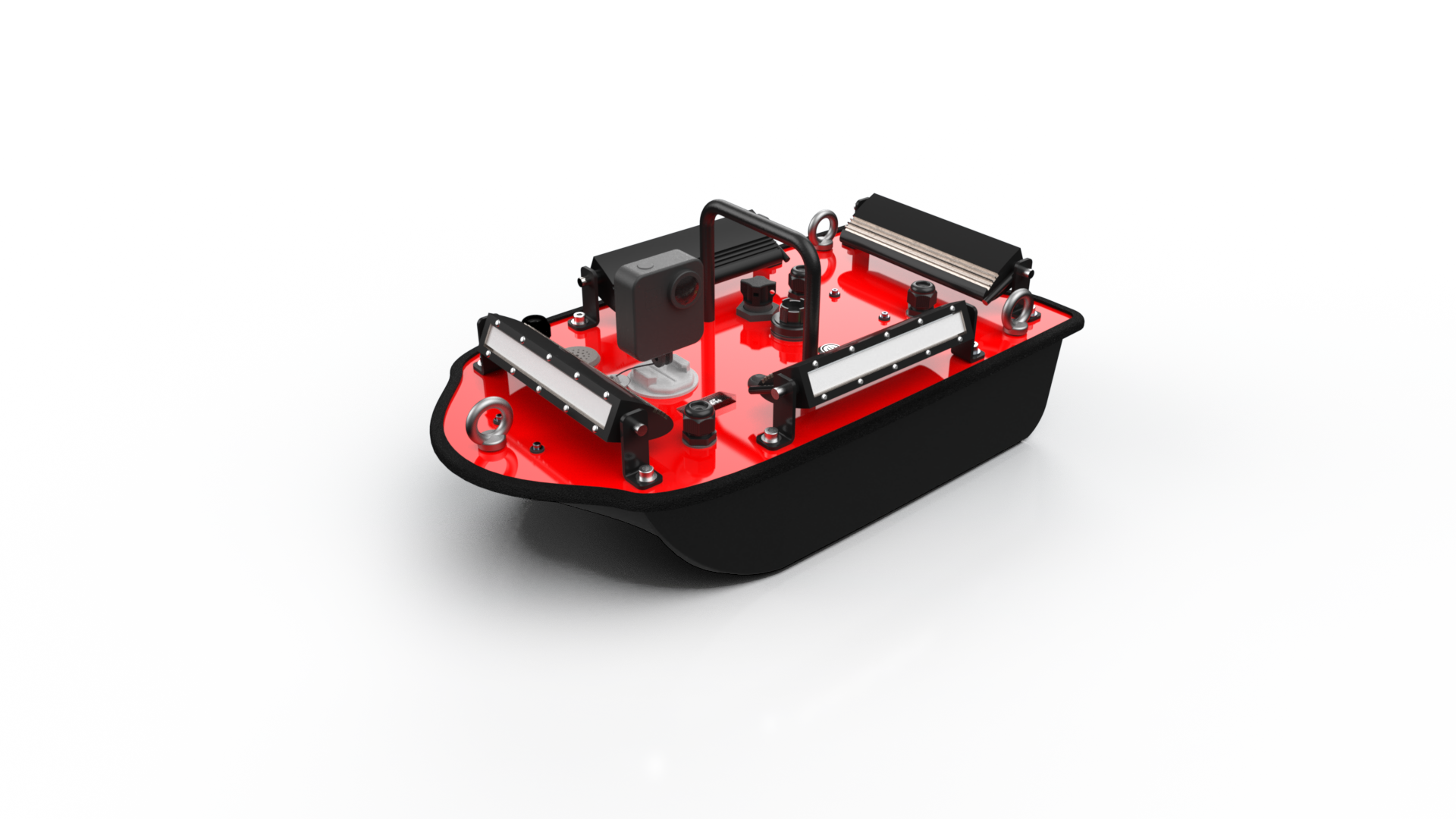

ViewPoint, is a 30-year specialist in video image processing for medical and environmental research. In partnership with INRAE (French Research institute on Agronomy and Environment) ViewPoint has developed ToxMate, an innovative solution to detect harmful substances in water on site and in real time. ToxMate measures the real-time impact of the presence of chemical pollutants on living organisms.

Micropollutants are invisible, but it is has been proven that they can have consequences on our environment and on our human health. While physico-chemical sensors and analysis show their limits to identify the presence of micropollutants (punctual sampling, long analysis times, limitation of the number of targeted molecules, high costs etc …), biomonitoring appears to be the best way to provide a rapid, reliable, global and continuous response to the detection of emerging contaminants of concern.

Implanted on site, ToxMate continuously analyses, by videotracking, the individual behaviour of 3 aquatic invertebrates species. The collected datas are instantly processed and analysed and an alert is triggered within minutes if a pollution is detected.

ToxMate detects chemical substances on raw, drinking or waste water , onsite and 24/7 .

The 3 species of aquatic invertebrates present in the station (gammarus, radix and leeches) react to a wide variety of toxic substances and are considered as the best bio-indicators of the level of water pollution.

Deployed in waste water plants; drinking water plants, alert stations or for reuse applications, ToxMate has already demonstrated it’s sensitivity not only to chemical molecules, but to cocktail and recombination effects as well.

ToxMate : a management tool for continuous control of your site

– Continuous monitoring of water flow

– Immediate detection at low concentrations (μg/L to the order of one minute)

– Sensitivity to cocktail effects

– Alert triggered within minutes in case of micropollutants

– notification of plant managers in case of an alert, by sms or email

– Tracking available online via a secure access

– Data restated for immediate understanding

– Historization of data to better understand and manage, understand recurrence factors and classify different types of events.

– A complete support to optimize the contribution of ToxMate on your site.

Applications :

– Urban/Industrial wastewater plant upstream to characterize the quality of the incoming water and optimize the process. And/or downstream to detect toxicity risks before discharge into the natural environment.

– Drinking water plant at the end of the treatment to determine its performance, and upstream on incoming raw water.

– Alert station : for continuous analysis of surface waters in rivers, in the upstream of a water intake point.

– REUSE : for continuous analysis of treated waste water in view of their reuse for different purposes, such as agricultural irrigation, street cleaning etc …

Meet ViewPoint Water Biomonitoring at IFAT 2024, Booth C1-519

Innovation !

Detection of micro-pollutants thanks to aquatic macro-invertebrates: Optimal solution for real-time water quality monitoring for municipal or industrial wastewater treatment plants, drinking water plants and wastewater reuse.

Discover ToxMate biomonitoring – Hall C1 Booth 519.

Are you concerned about the presence of micropollutants in your water treatment plant? Need to characterise the chemical quality of incoming water or wastewater and looking for solutions to optimise processes? We provide a practical solution for managers of WWTPs, drinking water treatment plants, etc.

Meet us in Hall C1-519

Micropollutants are invisible, but they have consequences for the environment and human health. Cosmetics, detergents, solvents, medicines, etc. – there are more than 200,000 molecules present in the aquatic environment, and detecting them is complex. Have you thought about real-time, on-site biomonitoring?

Discover ToxMate – Hall C1 Booth 519

CONTACT US

E-mail : info@toxmate.fr

Tél. : +33 (0)4 72 17 91 92

67 RUE COPERNIC – TECHNOPARC – 01390 CIVRIEUX

Website: www.toxmate.fr/en/