HALL C2 – Stand 423

#valvemanufacturer #valvesquality #choosequality #tecfly #tecknife #valveinnovation

about us :

TECOFI is a French valve manufacturer, global company we offer solutions in the WATER, HVAC and INDUSTRIAL sectors.

Valve manufacturer, we offer solutions in the WATER, HVAC and INDUSTRIAL sectors. We guarantee quality products conform to the latest standards. Our know-how, thanks to our design office and our technical team, provides our partners with flexibility and reactivity. Present in more than 100 countries, we have a vast geographic presence. Concerned with our environmental impact, we are ISO 9001 and 14001 certified. With references in large water projects around the world, TECOFI has becomes a key player!

TECFLY : butterfly valve model VPG.

Our new TECFLY butterfly valve type VPG offers you the best quality-to-price ratio on the market. Intended for use in fluid transfer circuits such as clear water, wastewater, liquid waste and for the HVAC sector, it has already become a must on market!

With its customised TECOFI handle, the brand is visible!

Built with a single axis to reduce pressure loss thanks to a thinned and profiled butterfly, it ensures an excellent flow of the fluid, in particular for small diameters. Its flexible sleeve and through shaft guarantee a perfect seal in both directions of the pipe flow.

Available with a cast iron or stainless steel disc. ACS, Nitrile and Viton sleeves available.

In stock, we can adapt different types of actuation.

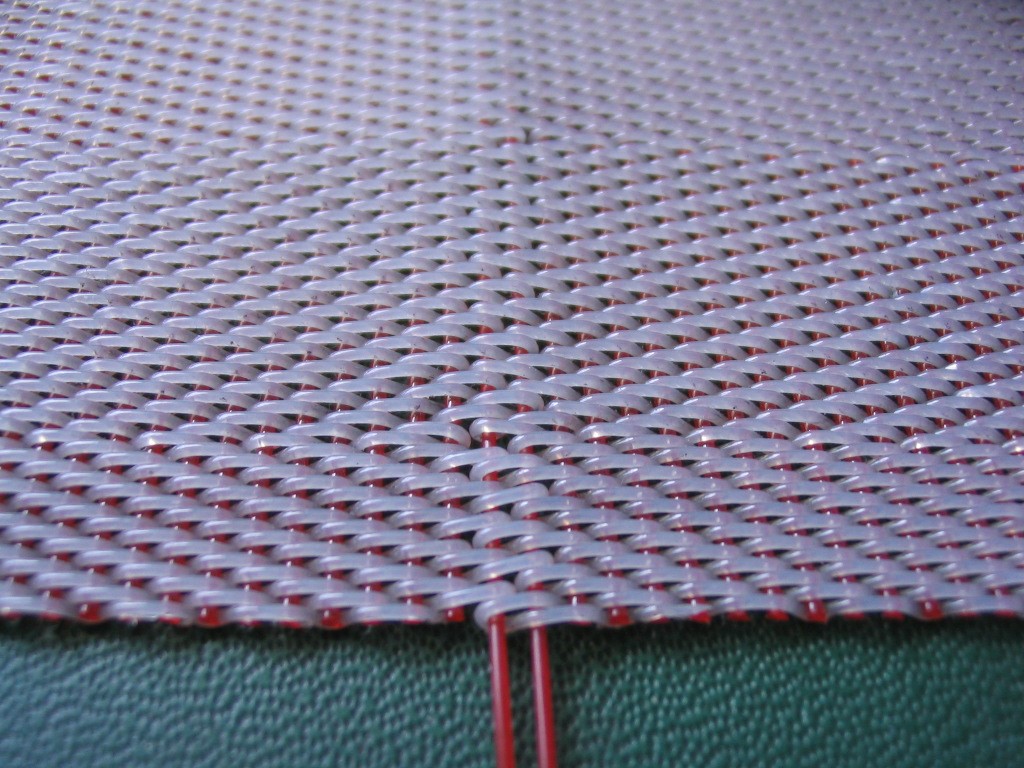

TECKNIFE : knife gate valve full range

OUR RANGE IS EVOLVING FOR INCREASED RESISTANCE !

Full Knife gate valve range in Ductile Iron (GGG50)

All our TECOFI range is now available in Ductile Iron EN-GJS-500-7 (GGG50).

Ductile iron stands out from other traditional cast irons due to its remarkable mechanical properties (elasticity, shock resistance, elongation, etc.). Discover at our booth our TECKNIFE in Ductile Iron with epoxy coating according to the GSK DIRECTIVES which ensures excellent corrosion protection.

CONTACT US

E-mail : c.salvado@tecofi.fr / d.oundjian@tecofi.fr

Tél. : +33 (0)6 70 55 60 25 / +33 (0)6 70 72 62 95

83 Rue Marcel Mérieux, 69960 Corbas – FRANCE

Website: www.tecofi.com