Booth 417/516.K

#flowmeter #gravityflow #accuaraty #water #sewage #innovation

about us :

Graviflow is a French startup that manufactures water flowmeters with an innovative patented technology.

Our water flowmeters are very precise, better than 98% exactitude, from small flows, on an effective range of 0.1% to 100% of the nominal flow, very easily to install on existing hydraulic structures without requiring significant work and are “plug & play”.

Our flowmeters are made of robust 316L stainless steel, machined with great precision.

Our flowmeters are made in standard diameters from DN100 to DN1200.

The maintenance is reduced. GRAVIFLOW flowmeters can be controlled on site without disassembly by a metrological procedure validated by water agencies.

We provide standard shims and gauges for in place metrological testing by the operator or an approved testing agency.

Available functions :

• alarms on thresholds,

• sampling equipment control,

• flow regulation (valve control),

• data logger option,

• low power option.

Areas of use (typical) :

• sewerage networks,

• water springs,

• industrial fluid networks,

• sewage treatment plants,

• combined sewer overflows,

• pumping stations inflow and overflow.

Decisive benefits :

• insensitivity to flow regime, even changing flow regimes,

• compact design,

• no field adjustment required,

• COFRAC connected hydraulic bench calibration certificate provided,

• low cost of the measuring point.

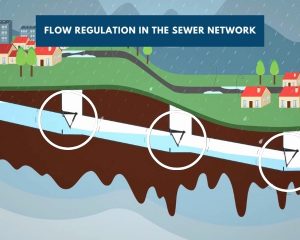

Hydraulic storage works

Overflow self-control on storm spillway

Characteristics of the work and installation :

- Passage manhole with entrance/exit

- Discharge pipe: DN500

- Nominal flow: 2100 m3/h

- Downstream surface mounting on the upstream wall of the structure

- Electronic box and display in the existing electrical cabinet

Operating conditions :

- GRAVIFLOW model in V2 adapted to flow measurement in conditions of downstream influence

- Partially submerged and permanent pipe

- Taking into account the downstream level by radar probe

Sending information to the existing Sofrel remote transmitter:

- Continuous flow measurement: 4-20mA

- Volume counting pulses: NO contact

- Flow threshold over-threshold alarm: NO contact

- Flow meter blocking alarm: NO contact

GRAVIFLOW, the solution in the case of gravity flow

The GRAVIFLOW process allows our flow meters to perform a fair and reliable measurement in most cases of gravity flow, and particularly in cases where other devices on the market are not satisfactory.

Best solution

When flow regimes are variable or turbulent our flow meter is the best solution.

Available functions :

- Real-time instantaneous flow measurement (4-20mA output)

- Calculation of total volume

- Volume counting pulses, not programmable

- Alarm on high or low flow threshold

- Measurement fault: blockage or internal fault

- Intuitive local communication interface via Bluetooth

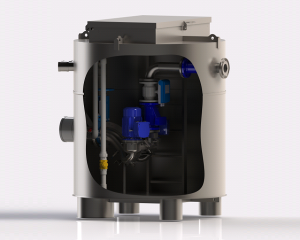

Pumping stations

Pumping station overflow

Characteristics of the work and installation :

- Outlet sight too full pumping station

- Discharge pipe: DN200

- Nominal flow: 160 m3/h

- Mounting between standardized flanges

- Electronic box in electrical box nearby

Operating conditions :

- Partially filled/full pipe

- GRAVIFLOW CLAP200 model in standard version

Sending information to the SOFREL remote transmitter of the SP:

- Continuous flow measurement: 4-20mA

- Volume counting pulses: NO contact

- Flow threshold over-threshold alarm: NO contact

- Flow meter blocking alarm: NO contact

Wastewater treatment plants

Flow regulation

Characteristics of the work and installation :

- Passage manhole with entrance/exit

- Discharge pipe: DN200

- Nominal flow: 160 m3/h

- Mounting between flanges downstream of the control valve

- Electronic box and display in the existing electrical cabinet

Operating conditions

- Pipe partially filled

- GRAVIFLOW model in V1 version without downstream influence

Sending information to the existing Sofrel remote transmitter:

- Continuous flow measurement: 4-20mA

- Valve control by existing automation

- Volume counting pulses: NO contact

- Flow threshold over-threshold alarm: NO contact

- Flow meter blocking alarm: NO contact

CONTACT US

E-mail : contact@graviflow.com

Tél. : +33 (0)3 89 39 13 64 – +33 (0) 7 77 77 66 33

2 rue des Peupliers 68920 WETTOLSHEIM

Website : https://graviflow.com